Indexing & Abstracting

Full Text

Research ArticleDOI Number : 10.36811/ojpsr.2020.110008Article Views : 8Article Downloads : 31

Physicochemical Properties and Stability of Microencapsulated Betacyanin Pigments from Red Dragon Fruit Peels and Flesh

Rosalinda C Torres*, Rowelain Mae G Yumang, Chelsea Kate F Jose and Danielle Camille P Canillo

Standards and Testing Division, Industrial Technology Development Institute, Department of Science and Technology, General Santos Avenue, Bicutan, Taguig City, Metro Manila, Philippines

*Corresponding Author: Rosalinda C. Torres, Standards and Testing Division, Industrial Technology Development Institute, Department of Science and Technology, General Santos Avenue, Bicutan, Taguig City, Metro Manila, Philippines, Email: rosalindactorres@gmail.com

Article Information

Aritcle Type: Research Article

Citation: Rosalinda C Torres, Rowelain Mae G Yumang, Chelsea Kate F Jose, et al. 2020. Physicochemical Properties and Stability of Microencapsulated Betacyanin Pigments from Red Dragon Fruit Peels and Flesh. Open J Pharm Sci Res. 2: 141-148.

Copyright: This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Copyright © 2020; Rosalinda C Torres

Publication history:

Received date: 23 December, 2019Accepted date: 02 January, 2020

Published date: 06 January, 2020

Abstract

Dragon fruit (Hylocereus polyrhizus) is known for its purple-coloured peels and pulp, which can be attributed to the presence of betalains. In this study, the potential of red dragon fruit as a source of natural colorant was investigated. Betacyanins were extracted from red dragon fruit peels and flesh in 1:3 ratio with water. Microencapsulation by spray-drying was done by adding 5% and 10% (w/v) maltodextrin (DE 11.8) to peels and flesh extracts, respectively. The spray-dried colorant powders all obtained <10% moisture content, 5.261-6.409 g/100g hygroscopic moisture content, and 5.317-7.349(mg/100L) betacyanin content. Morphological characterization revealed spherical, agglomerated particles with visible cracks on the surface. The stability study conducted showed that pigment retention was lowest at 70°C and highest at 4°C.

Keywords: Hylocereus polyrhizus; Red dragon fruit; Betacyanin; Microencapsulation; Physicochemical properties

Introduction

Synthetic colorants, despite having lower production cost and greater stability, have raised several health and ecological concerns [1-3]. Concerns have also been raised about the deleterious effects associated with artificial food dyes [4-6]. Products containing natural ingredients are generally perceived by the consumers to be of better quality, safer and healthier than those with synthetic compounds [7]. Recent trends show that consumers have been choosing products with natural colors due to their belief that these are healthier and safer, that is why there has been a growing interest in the development of natural colorants to replace synthetic colorants [8].

Anthocyanins are commonly used as natural colorants [9]. However, betalains are interesting alternative as they are more hydrophilic and have a higher tinctorial strength [10]. Thus, they are commonly used in the food industry as a source of natural red color. Betalains are water-soluble, nitrogen-containing natural pigments, which can be divided into two groups: red-violet betacyanins and yellow-orange betaxanthins [11]. The basic structure of betalains is betalamic acid linked to the molecule of cyclo-3,4-dihydroxyphenylalalnine (cyclo-DOPA) for betacyanins, and to the molecule of amino acid or amine for betaxanthins [10]. One of the common sources of betalain compounds is Hylocereus polyrhizus or red dragon fruit.

Dragon fruit or pitaya is one of the tropical fruits under the cactus family, Cactaceae. In general, there are two species of dragon fruits commonly found in the Philippine market, i.e. red dragon fruit (Hylocereus polyrhizus) and white dragon fruit (Hylocereus undatus). H. polyrhizus, widely known for its sweet taste and deep purple coloured peels and pulp, has been identified as a promising natural source of colorants [12].

In general, production and application of natural pigments encounter several problems, such as the use of large amount of raw materials, higher concentration to produce desired color, and lower stability [13-14]. Factors such as temperature, pH, water activity, light, and the presence of metal cations, greatly affect the stability of betalain pigments, subsequently leading to a loss in color and functional properties [10]. Microencapsulation is a process wherein a core particle is trapped in a carrier material to isolate it from an external environment which may affect it. Microencapsulation by spray-drying has been widely used due to its low-cost, flexibility, continuous production, and easy industrialization [15-18]. It involves dispersing of the core materials in a polymer solution and atomizing in a hot chamber to produce a powder with good quality and low water activity. Due to its dried particulate form, the pigment can be transported and stored more easily [19-20].

Therefore, this study aims to microencapsulate red dragon fruit betacyanin pigments through spray-drying and establish the physicochemical properties of the colorant powder produced. It also aims to investigate the effects of different treatments on its stability. Knowing how factors such as pH, light, and temperature influence the colorant would be useful in its several applications in the industry.

Materials and Methods

Materials

The red dragon fruit used in this study was purchased from Silang, Cavite, Philippines. Maltodextrin (11.8 DE) and ascorbic acid (USP) were procured from Allyson’s Chemical Enterprises (Quezon City, Philippines). Analytical grade hydrochloric acid (Sigma-Aldrich, USA) and sodium hydroxide pellets (Sigma-Aldrich, USA) were purchased from Belman Laboratories (Quezon City, Philippines).

Plant Processing and Storage

Freshly sourced dragon fruits were washed well to remove dirt. Prior to the experiment, the plant materials were stored at -50°C for preservation. The peels were separated from the flesh and then both were cut into smaller, uniform pieces.

Extraction of betalain from red dragon fruit peels and flesh

The pulps were subjected to liquid-solid extraction using deionized water (1:3) while the pulp were homogenized with water (1:3) using a laboratory waring blender. Both mixtures were extracted overnight at 4°C with periodic agitation, then separately filtered using cheesecloth to remove the other plant materials present in the extract.

Microencapsulation of betalain

Microencapsulation was done by completely dissolving maltodextrin (11.8 DE) at 5% and 10% (w/v) concentrations in the dragon fruit peels and pulp extracts, respectively. The microencapsulation process was carried out using a spray-dryer with the following parameters: 150 °C inlet temperature, 15 mL/min flow rate, and 2kg/cm3 air-flow pressure.

Physicochemical properties of spray-dried powder

Determination of moisture content

The moisture content was measured based on the Association of Official Analytical Chemists (AOAC) method. One gram of the microencapsulated powder was weighed in the pan and the temperature of Moisture Balance MOC-120 H was set to 105°C. The procedure was done in triplicate.

Color analysis

Quantification of color was done using Lovibond LC 100 Spectrocolorimeter calibrated with a white standard plate. The powder was contained in an optical cell and the L*, a*, and b* values were measured in triplicate.

Determination of betacyanin content

The betacyanin content of the microencapsulated powder was determined spectrophotometrically according to the method of Lim et al [21]. Approximately 0.2 g of the colorant powder was dissolved in deionized water and diluted in a 25 mL volumetric flask. The absorbance was read at 536 nm using L7 Double beam UV-Vis spectrophotometer and the betacyanin content was calculated using the formula:

Beatacyanin Concentration

wherein A = Absorbance (λ 538 nm), DF = Dilution factor, MW = Molecular weight of betacyanin (550 g/mol), = Molar extinction coefficients (60,000 L/mol cm), and l = Path length of cuvette (1.0 cm).

Hygroscopicity

The hygroscopicity of the microencapsulated powder was determined according to Cai and Corke [22]. One gram of the powder was weighed and stored at room temperature in a dessicator with saturated NaCl solution (67% RH). The weight of the sample was obtained after a week and the hygroscopicity was expressed as gram of adsorbed moisture (g/100 g) dry solids.

Particle Size Distribution

The particle size distribution analysis was conducted by UPLB Nanotech Lab. The samples were suspended in HPLC grade water and then subjected to Malvern Zetasizer NanoSeries Nano-ZS90. Particle size analysis was done using dynamic light scattering technique in automatic mode. Average particle size was determined through three measurements at 90°.

Morphological Characterization of the Microencapsulated Powder

The morphology of the microencapsulated powders was viewed using a scanning electron microscope (Phenom X, ThermoFisher Scientific). The powder samples were mounted on separate pin stubs and then applied with a thin layer of gold through sputter coating technique using a fine coater (JFC-1200 Fine Coater, Jeol). The average size of 100 particles in the image was obtained using ImageJ software.

Stability of the Pigment

The microencapsulated pigments from dragon fruit peels and pulps were subjected to different treatments. The powder was dissolved in different solutions and subsequently stored at various conditions. The absorbance was read at 536 nm at appropriate times. The pigment retention is expressed as

Pigment Retention (%)

Statistical Analysis

All measurements were done in triplicate (n=3). Data analysis was carried out using SPSS version 15 and Microsoft Excel 2013.

Results

Microencapsulation of Betacyanin Pigment

The physicochemical properties of the colorant powders can be seen in Table 1. All colorant powders obtained a moisture content of <10%, making it safe against microbial growth [23]. In comparison to feed with 10% (w/v) maltodextrin, the 5% (w/v) maltodextrin concentration produced colorant powders with higher moisture content compared to that of 10% maltodextrin.

|

Table 1: Physicochemical properties of colorant powder from red dragon fruit extracts, spray-dried at 150 °C. |

||||

|

Powder |

Moisture Content |

Hygroscopicity |

Betacyanin Content |

|

|

(g/100g) |

(mg/100L) |

|||

|

Peels |

Batch 1 |

5.228 |

6.063 |

5.317 |

|

(5% MD) |

Batch 2 |

4.847 |

5.261 |

5.281 |

|

Pulps |

Batch 1 |

4.95 |

6.497 |

7.349 |

|

(10% MD) |

Batch 2 |

4.7567 |

5.466 |

6.595 |

The hygroscopicity of the colorant powders ranged from 5.466 – 6.497 (g/100 g). Hygroscopicity refers to the ability of a material to take up water vapor from the atmosphere at constant temperature [24]. Addition of maltodextrin has been known to help decrease the hygroscopicity by absorbing water, thus forming a moisture-protective barrier on the surface of encapsulated material [25].

Betaxanthin is not present in red dragon fruit, making betacyanin responsible for its color [12]. Addition of higher maltodextrin concentration produced spray-dried powders with higher betacyanin content. Increase of solids content in the feed promotes bioactive retention, due to the ability of maltodextrin to reduce oxygen permeability of the wall matrix [26].

Color was evaluated using Hunter ‘L’ (lightness), ‘a’ (‘+a’, redness and ‘-a’, greenness), and ‘b’ (‘+b’, yellowness and ‘-b’, blueness). Table 2 shows the L, a, b values of the colorant powders during week 0 and week 5. All powders had a ‘+a’ value and ‘-b’ value. Addition of 5% (w/v) maltodextrin to the extract produced colorant powders with higher ‘L’ and ‘b’ values, and lower ‘a’ values compared to the addition of 10% (w/v) maltodextrin. This agrees with the finding that L value is inversely proportional to the betacyanin content [27].

|

Table 2: Color analysis at week 0 and week 5 of colorant powders. |

||||||||

|

Powder |

Week 0 |

Week 5 |

(ΔE) |

|||||

|

L |

A |

B |

L |

a |

b |

|||

|

Peels |

Batch 1 |

66.8 |

21.9 |

-8.8 |

67.9 |

21.5 |

-7.4 |

0.8062 |

|

(5% MD) |

Batch 2 |

66.1 |

26 |

-9.7 |

67.3 |

26.4 |

-9.1 |

0.6 |

|

Pulps |

Batch 1 |

62.5 |

32.5 |

-18.9 |

63.5 |

34.3 |

-20.7 |

1.8 |

|

(10% MD) |

Batch 2 |

64.4 |

30.3 |

-17.7 |

64 |

33.3 |

-19.9 |

2.2 |

Particle Size Distribution

Particle size distribution affects the physical properties of the powders such as bulk density, angle of repose, flowability, rehydration capacity, solubility, and dispersibility [28]. The z-averages (d.nm) and PDI values can be seen in Table 3. The Z-average of pigments encapsulated with 10% w/v maltodextrin was higher with 921.1± 64.02, while that of 5% (w/v) maltodextrin was 169.7± 21.33. These results were consistent with previous findings that particle size increases with feed concentration. Other factors that affect the particle size include parameters in the formulation and spray-drying process such as droplet size and solubility of solute [29-30].

|

Table 3: Particle size distribution of red dragon fruit peels and flesh. |

||||

|

|

Z-average (d. nm) |

RSD |

PdI |

RSD |

|

Peels |

169.7± 21.33 |

12.60% |

0.801± 0.092 |

11.40% |

|

(5% w/v MD) |

||||

|

Flesh |

921.1± 64.02 |

6.95% |

1.000 ± 0.000 |

0.00% |

|

(10% w/v MD) |

||||

Morphology of microencapsulates

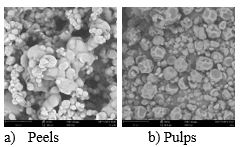

The microencapsulated betacyanin pigments are shown in Figure 1. The image reveals spherical, agglomerated particles with visible cracks on the surface. Shrinking of the particles during drying and cooling caused the outer surface of the particles to dent [31]. Imperfections on the surface of the microparticles such as irregular shapes, cracks, and denting form due to the delay of the film formation process during the drying process [32].

Figure 1: Micrographs of microencapsulated betacyanin pigments of dragon fruit a.) peels and b.) Pulps

Stability of pigment

Table 4 shows the effect of different treatments and storage conditions in the betacyanin pigment retention of the spray-dried powders.

Effect of pH

In both samples, a huge difference in the color and betacyanin content in the acidic and basic medium has been observed. Both Treatment B solutions exhibited a yellow-brown color, in contrast to the pink solutions of Treatment A. Betacyanin is unstable in alkaline conditions because it undergoes dehydrogenation, producing a yellow betalamic acid and colorless cyclo-Dopa 5-O-β -glucoside. This was evident in the hypochromic shift. On the other hand, acidic conditions allow for the regeneration of betacyanin through the recondensation of betalamic acid with cyclo-dopa 5-O-β-glucoside [33].

|

Table 4: Pigment retention of colorant powders in different treatments and storage condtions. |

||

|

Treatment |

PIGMENT RETENTION |

|

|

PEELS |

FLESH |

|

|

Acidic (A) |

52.38829 |

76.0274 |

|

Basic (B) |

29.0545 |

29.01371 |

|

Oxidation |

19.15655 |

23.29492 |

|

Light |

61.96318 |

72.24462 |

|

Dark |

76.22517 |

79.75032 |

|

4°C |

93.42677 |

99.0339 |

|

50°C |

59.8218 |

58.30059 |

|

70°C |

17.88107 |

18.35831 |

Effect of light

Higher pigment retention was observed upon storage of the colorant powders in the dark. Betalains have been reported to have higher degradation rate under exposure to light. The mechanism proposed that the electrons of the betalain chromophore are excited to a more energetic state upon absorption of UV light. This results to an increase in the reactivity of the molecule and subsequently, a decrease in its activation energy [34].

Effect of temperature

Highest pigment retention was observed in 4°C, while the lowest was observed at 70°C. Temperature is said to be the most crucial factor on the stability of betalain pigments. It is said that betalain stability considerably declines within the temperature range of 50-80°C [35-36]. Thermal degradation of betacyanin in purple pitaya juices follows first-order reaction kinetics, and it is also a function of temperature and heating period. Upon thermal treatment, decarboxylation and dehydrogenation of betanin occurs. This hypochromic shift from 538 nm to 505 nm results to an orange-red appearance and yellow tint [10,37,38].

Conclusion

Microencapsulation of betacyanin pigments from red dragon fruit peels and flesh produced powders with good color, moisture content, and hygroscopic values. The stability of microencapsulated betacyanin pigments from red dragon fruit peels and flesh is greatly affected by pH, light, and temperature. Results show that betacyanin content of colorant powders stored at 70°C decreased by 82-83%, while they were most stable at 4°C. Because of these results, red dragon fruit may further be developed as a source of natural colorant.

Acknowledgment

The authors would like to thank the Philippine Council for Industry, Energy and Emerging Technology Research and Development (PCIEERD) for funding this project.

References

1. Potera C. 2010. The artificial food dye blues. Environ. Health Perspect. 118: 428. Ref.: https://bit.ly/37xkeZf

2. Feng J, Cerniglia CE, ChenH. 2012. Toxicological significance of azo dye metabolism by human intestinal microbiota. Front. Biosci. 4: 568-586. Ref.: https://www.ncbi.nlm.nih.gov/pubmed/22201895

3. Dotto GL, Pinto LA, Hachicha MA, et al. 2015. New physicochemical interpretations for the adsorption of food dyes on chitosan films using statistical physics treatment. Food Chemistry. 171: 1-7. Ref.: https://www.ncbi.nlm.nih.gov/pubmed/25308634

4. Amchova P, Kotolova H, Ruda-Kucerova J. 2015. Health safety issues of synthetic food colorants. Regulatory Toxicology and Pharmacology. 73: 914-922. Ref.: https://www.ncbi.nlm.nih.gov/pubmed/26404013

5. El-Wahab HM, Moram, GS. 2012. Toxic effects of some synthetic food colorants and/or flavour additives on male rats. Toxicology and Industrial Health. 29: 224-232. Ref.: https://bit.ly/39qYJLr

6. Stevens IJ, Kuczek T, Burgess JR, et al. 2013. Mechanisms of behavioral, atopic, and other reactions to artificial food colors in children. Nutrition Reviews. 71: 268-281. Ref.: https://www.ncbi.nlm.nih.gov/pubmed/23590704

7. Martins N, Roriz CL, Morales P, et al. 2016. Food colorants: challenges, opportunities, and current desires of agro-industries to ensure consmer expectations and regulatory practices. Trends Food Sci. Technol. 52: 1-15. Ref.: https://bit.ly/2Qf7518

8. Burrows A. 2009. Palette of our palattes: a brief history of food coloring and its regulation. Comprehensive Reviews in Food Science and Food Safety. 8: 394-408. Ref.: https://bit.ly/35cGIND

9. Chung C, Rojanasasithara T, Mutilangi W, et al. 2016. Enhancement of colour stability of anthocyanins in model beverages by gum Arabic addition. Food Chemistry 20: 14-22. Ref.: https://www.ncbi.nlm.nih.gov/pubmed/26868542

10. Herbach KM, Stintzing FC, Carle R. 2006. Betalain stability and degradation-structural and chromatic aspects. J. Food Sci.71: 41-50. Ref.: https://bit.ly/2Fbyuui

11. Ravichandran K, Saw NMT, Mohdaly AAA, et al. 2003. Impact of processing of red beet on betalain content and antioxidant activity. Food Research International. 50: 670-675. Ref.: https://bit.ly/39pT2NE

12. Le Bellec FL, Vaillant F, and Imbert E. 2006. Pitahaya (Hylocereus spp.): a new fruit crop, a market with a future. Fruits. 61: 237-250. Ref.: https://bit.ly/2FelRic

13. Rodriguez-Amaya DB. 1999. Changes in carotenoids during processing and storage of foods. Arch. Latinoam. Nutricion, 49: 38-47. Ref.: https://bit.ly/2QFUpPI

14. Sigurdson GT, Tang P, Giusti MM. 2017. Natural colorants: food colorants from natural sources. Annu Rev Food Sci Technol. 8: 261-280. Ref.: https://bit.ly/2QI4vQ4

15. Jyothi NV, Prasanna PM, Sakarkar SN, et al. 2010. Microencapsulation techniques, factors influencing encapsulation efficiency. Journal of Microencapsulation. 27: 187-197. Ref.: https://www.ncbi.nlm.nih.gov/pubmed/20406093

16. Wisniewski R. 2015. Spray Drying Technology Review. Proceedings of the 45th International Conference on Environmental Systems; Bellevue. 12-16. Ref.: https://bit.ly/2SMTvUe

17. Sun-waterhouse D, Wadhwa SS, Waterhouse GIN. 2013. Spray-drying microencapsulation of polyphenol bioactives: a comparative study using different natural fibre polymers as encapsulants. Food Bioprocess Technol. 6: 2376-2388. Ref.: https://bit.ly/2u9iRBr

18. Tan SP, Kha TC, Parks S, et al. 2015. Optimising the encapsulation of an aqueous bitter melon extract by spray-Drying. Foods. 2: 400-419. Ref.: https://www.ncbi.nlm.nih.gov/pubmed/28231214

19. Cano-Chauca M. 2005. Effect of carriers on the microstructure of mango powder obtained by spray drying and its functional characterization. Innov. Food Sci. Emerg. Technol. 6: 420-428. Ref.: https://bit.ly/37tSNzi

20. Quek SY. 2007. The physicochemical properties of spray-dried watermelon powders. Chem. Eng. Process. 46: 386-392. Ref.: https://bit.ly/2Qz8Wg8

21. Lim SD, Yusof YA, Chin NL, et al. 2011. Effect of extraction parameters on the yield of betacyanins from pitaya fruit (Hylocereus polyrhyzus) pulps. J Food Agr Environ. 9: 158-162.

22. Cai YZ, Corke H. 2000. Production and properties of spray-dried amaranthus betacyanin pigments. Journal of Food Science, 65: 1248-1252. Ref.: https://bit.ly/35bOMOw

23. Mercer DG. 2011. Challenges facing development within the agri-food sector of sub-saharan africa. Procedia Food Science. 1: 1861-1866. Ref.: https://www.sciencedirect.com/science/article/pii/S2211601X11002744

24. Newman A, Reutzel-Edens S, Zografi G. 2008. Characterization of the “hygroscopic” properties of active pharmaceutical ingredients. J Pharm Sci. 97: 1047-1059. Ref.: https://www.ncbi.nlm.nih.gov/pubmed/17630643

25. Tong HH, Wong S, Law MW, et al. 2008. Anti-hygroscopic effect of dextrans in herbal formulations. Int. J. Pharm. 363: 99-105. Ref.: https://www.ncbi.nlm.nih.gov/pubmed/18706495

26. Sansone F, Mencherini T, Picerno P, et al. 2011. Maltodextrin/pectin microparticles by spray drying as carrier for nutraceutical extracts. J Food Eng. 105: 468-476. Ref.: https://bit.ly/2ZKJFE4

27. Phebe D, Chew MK, Suraini AA, et al. 2009. Red-fleshed pitaya (Hylocereus polyrhizus) fruit color and betacyanin content depend on maturity. Int. Food Res. J. 16: 233-242. Ref.: https://bit.ly/2sDjcvK

28. Onwulata C. 2005. Particle size analysis of food powders. in Encapsulated and Powdered Foods. 217-248. Ref.: https://bit.ly/2MIxrq7

29. Elversson J, Millqvist?Fureby A, Alderborn G, et al. 2003. Droplet and particle size relationship and shell thickness of inhalable lactose particles during spray drying. Journal of Pharmaceutical Sciences. 92: 900-910. Ref.: https://bit.ly/37pXKt5

30. Elversson J, Millqvist-Fureby A. 2005. Particle size and density in spray drying - effects of carbohydrate properties. Journal of Pharmaceutical Sciences. 94: 2049-2060. Ref.: https://www.ncbi.nlm.nih.gov/pubmed/16052553

31. Amin ZM, Koh SP, Syazwani N, et al. 2018. Optimization of spray drying parameters for broken rice maltodextrin powder and its microencapsulation efficiency study on VCO microcapsule. J Nutr Health Food Sci. 6: 1-8. Ref.: https://bit.ly/2MOeHWl

32. Alves AI, Rodrigues MZ, Pinto MR, et al. 2017. Morphological characterization of pequi extract microencapsulated through spray drying. Int J Food Prop. 20: 1298-1305. Ref.: https://bit.ly/36tzHJq

33. Schwartz SJ, von Elbe JH. 1983. Identification of betanin degradation products. Eur Food Res Technol. 176: 448-453. Ref.: https://bit.ly/2MPxdxg

34. Jackman RI, Smith JL. 1996. Anthocyanins and betalain. natural food colorants. Blackie Academic and Professional, London. 244-309. Ref.: https://bit.ly/2QDMdQ3

35. Haklikova L, Mikova K, Kyzlink V. 1983. Heat stability of betacyanins. Z Lebensm Unters Forsch. 177: 247-250. Ref.: https://bit.ly/2FaHgJa

36. Saguy I, Kopelman IJ, Mizrahi S. 1978. Thermal kinetic degradation of betanin and betalamic acid. J. Agric. Food Chem. 26: 360-362. Ref.: https://bit.ly/2FfpJ2p

37. Schliemann W, Kobayashi N, Strack D. 1999. The decisive step in betaxanthin biosynthesis is a spontaneous reaction. Plant Physiol. 19: 1217-1232. Ref.: https://bit.ly/2ZTvBYZ

38. Bilyk A, Kolodij MA, Sapers GM. 1981. Stabilization of red beet pigment with isoascorbic acid. J. Agric. Food Chem. 46: 4491-4495. Ref.: https://bit.ly/2SLAbXG