Indexing & Abstracting

Full Text

Original ArticleDOI Number : 10.36811/ojfnr.2021.110005Article Views : 99Article Downloads : 71

Investigating formulation of honey beverages (beer and liqueur)

Deressa Kebebe*, Meseret Gemeda and Teferi Damto

Holeta Bee Research Center, Oromia Agricultural Research Institute, Ethiopia

*Corresponding Author: Deressa Kebebe, Holeta Bee Research Center, Oromia Agricultural Research Institute, Ethiopia; E mail: dhek.ras96@yahoo.com

Article Information

Aritcle Type: Original Article

Citation: Deressa Kebebe, Meseret Gemeda, Teferi Damto. 2021. Investigating formulation of honey beverages (beer and liqueur). Open J Food Nutri Res. 2: 01-11.

Copyright: This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Copyright © 2021; Deressa Kebebe

Publication history:

Received date: 25 September, 2021Accepted date: 29 September, 2021

Published date: 25 October, 2021

Abstract

Beverages having alcohol are fermented from the sweeties in fruits, berries, grains, and such other ingredients as plant saps, tubers, honey, and milk. Fermented honey drinks may have been the earliest alcoholic beverages known to man. The aim of this study was to contribute to the gap of low brewing technology knowledge and scientific knowledge for an innovative application of honey in the beer and liquors production. In this study honey beverages were formulated using different amount of honey with spices, yeast, hop, fruit, alcohol with different alcohol contents, herbs like cinnamon, clove, ginger, vanilla, fruits and maize and finger millet grain ingredients. Quality of the products were assessed concerning physicochemical and microbiological analyses, sensory evaluation, estimation of shelf-life, cost and yield of the products to characterize the honey beverages three different liquors and nine beer beverages produced from honey and other different ingredients. The pH value, total acidity, total soluble solid and ethyl alcohol contents of the formulated honey beverages were range from 3.8±0.03 to 6.1±0.010, 16.63±0.06 to 21.0±1.63 meq/kg, 21.30±0.56 to 36.87±0.50 % and 4.81±0.17 % to 44.10±0.50 %, respectively. Liquors and beer can be formulated from honey and other locally available materials to involve unemployed part of the societies as entrepreneurs to create their income.

Keywords: Beverages; Honey; Honey Beer; Honey Liquor; Ingredient

Introduction

Alcoholic beverages are produced in almost all countries worldwide and represents an important percentage on world´s economy. The honey beverages are a by-product of the processing of honey with different additives and yeast. Fermented honey drinks may have been the earliest alcoholic beverages known to man. Another hypothesis of the origin of alcoholic liquors is that they were first en-countered when wild fruits were stored in clay-lined holes in the ground. Honey, the sweet substance produced by honey bees, has been used for centuries to prepare traditional, homemade drinks. It contain energy giving carbohydrate, water soluble vitamins like thiamin, riboflavin, ascorbic acid, folic acid and etc [1-3]. For centuries it represented a universal sweetener and it has been used for a variety of alcoholic beverages, including honey beer. In food industry, especially among the brewers, using of natural ingredients is increasingly growing demand. Honey is a natural, sweet and viscous substance, which is characterized by highly valued nutritional and physiological properties. Beer is one of the most popular beverages in the world with evident positive effects on the overall health condition. It can be used as a base for developing a variety of products with specific physiological activity. Honey is standing out as one of the possible sources of active ingredients for that purpose. Recently it has been recognized that it has potential to become a major foreign exchange earner by making value added product of honey [4]. Diversification with value-added products therefore offers an opportunity to strengthen local markets which then permit a more solid beekeeping production to expand from a broad base into exportation. A lot of researches have been carried out in analyzing different honey value addition abroad.

An effort had been made to make honey beverages(honey beer and honey liqueur ) taking honey as the main ingredient and adding with sugar, different types of yeast ,aromatic chopped f1ruits or fruit pulp, herbs, flowers and/or spices ,70-90% alcohol with different ration concentration and fermentation time [4-6]. Given that honey production is a significant economic activity in our country, the development of honeyderived products appears to be a sound alternative to provide innovative alcoholic drinks to the consumers and to increase the profit of the beekeeping industry. In previous investigation in our country Tej (home processed, fermented alcoholic beverage) which is also commercially available as honey wine is the only produced product from honey value addition tried in our country [7]. Since the availability and quality of ingredients will vary from country to country, as will working conditions, customer preferences and marketing possibilities for the products trying the recipes under local conditions is recommended by Krell (1996). It is reported, the possibilities of using different and alternative honey beverages that can be available locally. So it is very important to use and test different locally available recipes for the production of different honey based beverages by adopting some major base formulations Moreover testing and utilizing of different locally available recipes suitable to socio economic conditions of the country are important to improve the local utilization of honey in beverages. Once methods of preparation of beverages are developed and large consumers are reached locally, exports may become more feasible. The aim of this work is to contribute to filling the gap of low brewing technology knowledge and scientific knowledge for an innovative application of honey in the beer industry.

Materials and Methods

Material procurement

The ingredients used in the formulations included, honey which was harvested during honey harvesting spring season of a year. Necessary ingredient such as spices, yeast, hop, grain and fruit alcohol with different alcohol contents indicated in the methodology, spices and herbs like cinnamon ,clove ,coriander ,ginger ,vanilla, fruits like orange ,apple and grain (maize and finger millet) and other necessary materials were purchased and prepared for processing from local markets and finfinnee.

Formulation of the honey beverages

Several different treatments were applied for conducting the preliminary experiment to standardize ingredients in an appropriate proportion. The proportions of ingredients required for the formulation of the beverage were determined by blending the selected ingredients through “trial and error method”. For this purpose, three beers and nine liqueurs of honey were tested and observed based previous value addition work [8,9] and making some changes on ingredients.

Formulations of different honey beers

The three honey beer formulated were made from honey, water, hops, yeast, sugar, maize, finger millet and other ingredients as mentioned below.

Honey Beer Recipe 2 (HBR2)

In formulation of this recipe that was % by W or V were 500 g honeys, 2 kg sugar, 4.5 Lt Water, one tea spoon of dry yeast and 5 slices of fresh ginger root. From bee product, 500g of honey with 2 kg of sugar in 4. 5 liter of water and 1 teaspoons of dry yeast were be added. Five (5) ginger root slices were added to accelerate the fermentation process and to help the yeasts in sugar metabolization process. The fermentation was taken place in a dark and warm room. After fermentation, the beer was crudely filtered and the ginger root slices were removed.

Formulation of different honey liqueur

The alcoholic portion of the liqueur is not derived from honey fermentation, but through the addition of alcohol in its pure form or as a distilled beverage such as aquavit, schnaps, gin, vodka, cachassa, rum or arrack and other alcohol [4,6]. Accordingly, nine formulations of honey liquors with different ratios and combination of honey, fruits, herbs, spices and alcohol contents were prepared and observed.

Honey liqueur recipe 5 (HLR5)

Formulation of this liqueur (% by weight/volume) was performed using 400 gram Honey, 160 ml cup Water, 0.5 teaspoon of vanilla extracts, 4 teaspoon Nutmeg, 8 cinnamon Sticks, 2 whole Cloves, 1 lemon, Zest Of, Peels Cut in Strips and 750ml Vodka. Honeys with water, vanilla, spices and lemon peel were combined in pot. Bring to a boil and let it was taken to boil to perk for 7 minutes and removed from heat. Then, the vodka was added to it. When slightly cooled, it was strained and poured into heat-proof 500 ml bottle. After cooling and checking for sediment under the bottle, the sensory and other quality parameters were undertaken.

Honey liqueur recipe 6 (HLR6)

In this formulation process 400 g of Honey, 500 ml of Vodka and 250ml of Water were used as ingredients. Honey, water and vodka were combined in washed and dried glass ware stirrign well until all the honey dissolves completely. the jar with vodka and honey stored in a cool place away from sunlight for one month stirring the contents with wood spoon once a week. The jar was stored for two more weeks. After the two weeks of aging, the honey liqueur was bottled. Honey liqueur was poured into the bottle using a funnel.

Honey liqueur recipe 8 (HLR8)

In formulation (% by weight/volume) of this recipe, 3750 ml clear alcohol vodka, 250 g honey 1 medium cinnamon sticks and zest of 1 orange were used as ingredients. The honey was decanted into a pan. Then, cinnamon of sticks and Zest of oranges were added. It was simmered after taking to a boil for 10 minutes. The clear alcohol added and it was removed from heat stept for several hours. Finally, it was poured into bottles and sealed until the time of characterization.

Quality assessment of the products

Quality is the ultimate criteria of the desirability of any food product to the consumers. Quality is a very important parameter for judging the edible nature of any food product (Sharma, 2006). Quality of the product will be assessed in terms of chemical constituents (viable count and sensory quality and shelf stability using standard techniques. These quality parameters were determined based on different methods which were mentioned below.

Physicochemical analysis

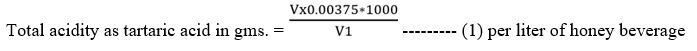

The pH was determined using a digital pH meter. The pH of samples was measured by dipping the electrode of a digital pH meter in the samples. The total acidity of samples was determined according to the total soluble solid (°Brix at room temperature) was determined using a refracto meter. Titratable acidities were determined by titrating 10 mL of the sample against a standardized solution of 0.1N NaOH with phenolphthalein as the indicator (AOAC, 1990).

Where, V1 = Volume of wine taken for estimation V = Volume of std. NaOH used for titration, in ml. The alcohol content was determined as a percentage volume by volume (%V/V) using specific gravity tables after distillation (AOAC, 1995) in laboratory of Ethiopian Conformity Assessment Enterprise.

Microbiological Analysis

Viable counts were determined in formulated beverages after storage. Viable count which is a method used in cell culture to determine the number of living cells in a culture is to make a distinction between live and dead cells. These counts were determined by pour plating selected serial dilutions of beverage in sterile MRS agar and incubating at 30°c for 48 hr. Yeast counts were determined by surface spreading selected serial dilutions of beverage on sterile prepared acidified potato dextrose agar and incubating at 30°c for 72 hr.

To count total coliforms, from a ten-fold appropriate serial dilution, 0.1 ml of aliquot was poured onto plates of violet red bile agar (Oxoid) (lactose, 10.0 g; peptic digest of animal tissue, 7.0 g; sodium chloride, 5.0 g; yeast extract, 3.0 g; bile salts mixture, 1.5 g; neutral red, 0.03 g, crystal violet, 0.002 g; agar, 15.0 g; distilled water, 1000 ml with pH of 7.4±0.2. Colonies were counted after the plates incubated under aerobic condition at 30-32°C for 20- 24 h (Deriba Muleta and Mogessie Ashenafi, 2002).

Sensory evaluation of the formulations

The prepared honey beverage with different levels of ingredients was subjected to sensory evaluation. Sensory evaluation was carried out based on the sensory parameters of color, flavor, taste, mouth feel and overall acceptability. An acceptance test was conducted with 60 consumers (10 women and 50 men), among them office staff between 22 and 56 years of age were used to determine the consumer acceptability of formulated beverages. The evaluation was carried out in individual attitudes. The panelists ranked acceptability of various attributes of different honey beverages samples using a nine-point hedonic scale (9 = like extremely, 8 = like very much, 7 = like moderately, 6 = like slightly, 5 = neither like nor dislike, 4 = dislike slightly, 3 = dislike moderately, 2 = dislike very much, 1 = dislike extremely). Before conducting the analysis, clear instructions were given to all the panelists and necessary measures were taken to remove various errors based on the combinations with highest mean ranks were selected for the further process. Sensory evaluation of the twelve honey beverages formulations was performed in two sessions, in the first session the consumers evaluated 12 honey beverages formulations and in the second session the different consumers evaluated the 4 best selected honey beverages. Each taster assessed, on average, 5 mL of honey beverages, which were served in 150 mL plastic cups coded with number and in a balanced order. The test was carried out in individual booths under white light and at 20 °C. The tasters were instructed in the use of the hedonic scale and to drink water between samples.

Estimation of Shelf-Life

The shelf life of the beverages is defined as the period of refrigerated storage (4°C) during which pH remained above 4.0 and the number of viable cell counts is above 10 cfu/ml. Refrigerated storage was carried out for 15 days with periodical observation of pH, total acidity and viability of starter culture.

Cost and yield of the products

The cost and yield of the beverage was carried out by accounting the cost of all the ingredients used for the formulation of beverage including the charges added as fuel, electricity and labor involved.

Statistical analyses

All fermentation experiments will be carried out in triplicate. All data generated from this study will be subjected to relevant statistical tools (ANOVA and Duncan’s Multiple Range Test) using SPSS software version 20 and significance was taken at 95% confidence level.

Results and Discussions

Physicochemical properties of honey beverages

General physicochemical properties of honey beer RHB2 and liquors RHL5, RHL6 and RHL8 were characterized. Preliminary physicochemical properties of the current honey beverage formulated were characterized based on pH, total acidity, total soluble solids, and ethanol contents for further adjustment. Table 1 presents the physicochemical properties of the four products. Moreover, color, flavor, taste, overall liking and mouth feel of the formed beverages were determined to show consumers’ acceptance based on sensory value (Table 1). Microbial counts were analyzed as indicated in Table 2 and aging time or shelf life of the products also estimated and the results were shown in Table 4. Cost of the ingredients used to formulate the products and the end useable yields were also recorded and compared as shown in table 5. As it can be seen in Table 1, average values of overall acceptability scores of the panelist’s sensory quality are greater than eight which implies the panelists liked the honey beer, RHB2. Color is a useful parameter for the characterization of the products because it is sometimes consumer’s preference. It also attracts drinkers to have it again and again in addition to other factors. The good golden color of the beer could be attributed to a high concentration of phytochemicals from the added honey ginger roots.

Honey beverage RH2 is liked extremely among the formulated beverages by the tasters. Honey liquor T5HL is the most liked beverages among the honey liquors formulated. The honey liquor most liked by color and flavor preference comparison based on sensory evaluation was RHL5 while honey beer (RHB2) was preferred of all the honey bevereges formulated based on taste, mouth feel and overall acceptability sensory parameters. Hadonic scale analysis also indicated that RHB2 was liked extremely by consumers. The honey liquors RHL5, RHL6 and RHL8 were also liked very much by the tasters, respectively.

Figure 1: Honey beverages formulated from different ingredients.

Figure 2: Honey Beer and liquors preferred by costumers and other parameters among formulated honey beverages .

The pH of the formulated honey beverages was found to range from 3.8±0.03 to 6.1±0.010, meaning it is acidic. Seferu and co-workers stated that the PH of different alcoholic beverages such as Lomie, Ananas, Dry gin, Ouzo, Vodka are 7.00 ± 0.01, 5.50 ± 0.01, 6.50 ± 0.01, 7.50 ± 0.04 and 5.90 ± 0.02, respectively [10]. The total acidity ranges from 1.63±0.06 to 21.0±1.63 while percent of total soluble solid is from 21.30±0.56 to 36.87±0.50 honey liquor T6HL having the highest soluble solid. The content of total solid across the factory produced beverage brands of Lomie, Ananas, Dy gin, Ouzo, Vodka were about 65 mg/L, 11667 mg/L, 10152 mg/L, 1256 mg/L and 11125 mg/L [10]. Alcoholic beverage, any fermented liquor, such as wine, beer, or distilled spirits, that has ethyl alcohol, as an intoxicating agent (Editors of Encyclopaedia Britannica, 2008). The Ethyl Alcohol contents of the beverages ranges from 4.81±0.17 % to 44.10±0.50 %. The alcohol contents is significantly different for the four selected honey beverages which may give preference for the consumers to select lower alcohol content beverage (RHB2) or the highest one (RHL8). Research has been conducted on Tej with alcohol content levels as low as 2.7% and as high as 21.7% [7]. The alcohol content of 391 beers and malt beverages available for sale in the State of Washington, the range of concentrations was 2.92% (v/v) to 15.66% (v/v) [11] in which ranges the new formulated honey beer also included. In some literatures it was stated that alcoholic content in beers range from about 2 percent to about 8 percent.

|

Table 1: Physicochemical properties and sensory evaluation of honey beer and liquors recipes (Mean ± SD). |

||||||||||

|

Honey bevereges |

N

|

Physicochemical Characterized |

|

|

Sensory Evaluated |

|

|

|||

|

PH value |

TA (me/Lt) |

TSS % |

Ethyl Alcohol % |

Color |

Flavor |

Taste |

MF |

OA |

||

|

RHB2 |

75 |

3.8±0.03a |

19.5±0.37a |

31.43±0.15a |

4.81±0.17a |

7.67±1.23a |

7.27±1.10a |

8.27±0.59a |

8.00±1.00a |

8.00±1.36a |

|

RHL5 |

90 |

5.89±0.09b |

16.3±0.06b |

36.13±0.12b |

28.63±0.60b |

7.89 ±0.90ab |

7.44±0.92ab |

7.33±1.24b |

7.17±1.34b |

7.22±1.06b |

|

RHL6 |

85 |

5.73±0.06bc |

19.5±0.04bc |

36.87±0.50bc |

22.02±1.05c |

7.35±2.12abc |

7.00±1.58abc |

6.59±1.46c |

6.24±2.25c |

6.71±2.20c |

|

RHL8 |

85 |

6.1±0.010bc |

21.0±1.63ad |

21.30±0.56d |

44.10±0.50d |

6.59±2.00d |

6.00±2.26d |

6.59±2.00cd |

5.94±2.38cd |

6.12±2.20cd |

|

Mean values with common letters in the same column indicate that there is no significant difference among samples (P > 0.05) from Tukey’s mean test. |

||||||||||

Where, HBR2 is honey beer recipe two, THL1 honey liquors recipe type one, THL8 honey liquors recipe type eight and THL8 is honey liquors recipe type eight, TA is to indicate total acidity, MF is to show mouth feeling, OA is abbreviation for overall acceptability while SD is standard deviation values.

Microbiological Analysis

Honey is not a sterile ingredients it has microorganisms (yeast and bacteria). Beyond bees, secondary sources of microbes in honey are humans, equipment, containers and wind [8]. Microorganisms of various groups appear to be involved in the fermentation of beverages indigenous to different parts of the world. The sources of the microorganisms are usually the ingredients and the traditional tools used for fermentation processes. Microbial fermentation makes the fermented beverge palatable as there will be an improvement on the organoleptic properties, texture, aroma, and flavor [12]. The alcoholic contents of Teji were measured and found in the range of 8.94–13.16% v/v ethanol. The RHB2 honey beer formulated Table 2 may be preferred to Teji for consumers that needing less alcoholic honey beverage.

However, the means counts of standard plate count and total coliform count of the samples were less than 3.0x106 cfu mL-1, respectively. On the basis of the Gulf Standards, it is clear that the colony counts of standard plate count and total coliform count in formulated honey beer and liquors exceeded the standard by considerable margin. From long history of its safety, the high counts of LAB may not pose hazard to the health of consumers.

|

Table 2: Microbial count in the different beverage preparations. |

|||||

|

Beverage code |

SPC |

|

TCC |

|

YMC |

|

cfu/mL |

Colony count range |

cfu/mL |

Colony count range |

Exponential cfu/mL |

|

|

RHB2 |

< 3.0X106 |

NG - TFTC |

< 3.0X106 |

NG |

1.3 X 104 |

|

RHL5 |

< 3.0X106 |

TFTC |

< 3.0X106 |

NG |

4.5 X 104 |

|

RHL6 |

< 3.0X106 |

NG - TFTC |

< 3.0X106 |

NG |

1.4 X 104 |

|

RHL8 |

< 3.0X106 |

NG - TFTC |

< 3.0X106 |

NG - TFTC |

7.4 X 103 |

|

Control |

0 |

NG |

0 |

NG |

0 |

|

Note: SPC=Standard plate count; TCC=Total coliform count; YMC= Yeast and mold count; TFTC=Too few to count; NG=No growth; cfu=colony forming units. |

|||||

Estimation of Shelf-Life

The shelf life of the beverages is defined as the period of refrigerated storage (4°C) during which pH remained above 4.0 and the number of viable cell counts is above 10 cfu/ml. A food products shelf life is one of the most important indicators characterizing the good or poor quality of product. Studies on the shelf life and storage conditions establishment for beverages are carried out to confirm compliance of the product with the established hygiene requirements during these periods, as well as to prevent their possible harmful effects on human health and the environment [13-26]. The pH value of the honey beer (RHB2) was reduced from 5.6±0.03 to 3.70±0.06 during storage time for eleven months (Table 3).

|

Table 3. Shelf life determination of the honey beverages. |

|||||

|

Honey Bevereges |

|

|

Shelf life parameters |

|

|

|

PH value |

|

TA, me/L |

Viable count, by Log in cfu/mL |

||

|

At the beginning |

After 10 MST |

At the beginning |

After 10 MST |

||

|

RHB2 |

5.6±0.03 |

3.70±0.06 |

19.5±0.037 |

4.21±0.71 |

16.05 |

|

RHL5 |

4.9±0.02 |

4.25±0.01 |

16.3±0.057 |

1.38±0.50 |

16.65 |

|

RHL6 |

5.6±0.03 |

5.16±0.05 |

24.9±0.056 |

4.37±0.08 |

16.05 |

|

HLR8 |

6.12±0.02 |

5.32±0.01 |

21.0±0.16 |

0.40±0.01 |

15.95 |

|

Where TA is Total Acidity, MST is month of storage. |

|||||

The pH values of formulated honey liquors RHL5, RHL6 and RHL8 were also reduced from 4.9±0.02 to 4.25±0.01, 5.6±0.03 to 5.16±0.05 and 6.12±0.02 to 5.32±0.01 as shown in Table 3, respectively. The storage time significantly affected the acidity level in the beverages; titratable acidity increased, whilst the pH was decreased. In parallel with pH values, the titratable acidity values of the beverages samples at the first eleven months of storage were insignificant Table 3.

Cost and yield of the products

The cost and yield of the beverage was carried out by accounting the cost of all the ingredients, labor, and electricity used for the formulation of honey beer and liquors including culture (inoculum) and overhead charges were also added as fuel which is criteria to demonstrate final products with good appearance by all parameters and long shelf life span to local entrepreneurs. The honey beer formulated in this study (RHB2) was produced using locally available materials and other cheaper inputs than other honey beverages. The relative current total cost of all inputs that was recorded during the honey beer and liquor formulation is listed in Table 4 as follow.

|

Table 4: Recent Cost Estimate and final yield of the honey beverages from the ingredients. |

|||||||

|

Honey Beverages |

Ingredients Cost, USD |

Labor USD |

cost, |

Fuel, USD |

Electricity cost, USD |

Total cost, USD |

Final Product, Lt |

|

RHB2 |

56.73293 |

82.14227 |

|

13.6903 |

2.327352 |

154.8921 |

38.900 |

|

RHL5 |

212.064 |

27.38076 |

|

13.6903 |

3.422576 |

256.5563 |

5.100 |

|

RHL6 |

161.5602 |

16.42845 |

|

13.6903 |

2.601158 |

194.2791 |

8.900 |

|

RHL8 |

967.2252 |

20.53557 |

|

13.6903 |

4.243994 |

1005.69 |

33.50 |

THB2, THL5, THL6, THL8 and cfu/cm are to indicate the cell frequency unit, Recipe of honey beer, Recipe of honey Liquor five, Recipe of honey Liquor six and Recipe of honey Liquor nine, respectively. In this study, honey liquor (RHL6) was made using the cheapest inputs and the next cheaper was RHL8 honey beverage (Table 4). The honey liquor beverage RHL5 was made using most expensive ingredients relatively as shown in table 4.

Conclusion and Recommendation

It has been found that when combined, the beverages of the honey and other ingredients can have better sensory and physic-chemical characteristics than when used individually. According to sensory and nutritional evaluation, the most recommended honey bee and honey liquor formulations is RHB2, RHL5 and RHL6, respectively. The consumers have a preference for honey beer composed of honey, sugar, dry yeast, water and ginger, sweeter and more acidic beverage and in relation to color, a lighter and less intense yellow color.

It should be noted that the raw materials used in this study, despite a low cost in Ethiopia, have a high cost worldwide, which may limits the production of this kind of products. The results shows that honey beverages can be prepared from local available ingredients using simple test and systematic ways to develop an acceptable, shelf stable honey beer and liquor. Based on tests on different honey beverages preparation methods, RHB2 was the suitable one selected to local conditions. It is recommended to small scale enterprises, users, beekeepers and non-beekeepers to get additional income or use for different ceremony.

References

1. Canini A, E Pichichero, D Alesian. 2009. Nutritional and botanical interest of honey collected from protected natural area. Plant Biosynthesis.143: 62-70.

2. Kibben J, N Engeseth. 2002. Honey as protective agent against lipid oxidation in round turkey. J Agric food chem. 50: 592-593. Ref.: https://pubmed.ncbi.nlm.nih.gov/11804534/ DOI: https://doi.org/10.1021/jf010820a

3. Wang J, Li X. 2011. Chemical composition, characterization and differentiation of honey botanical and geographical origins. AD Food Nutrition Res.

4. Krell R. 1996. Value added products from beekeeping. FAO Agriculture services bulletin. Food and agriculture organizations of United Nations. 92: 5-10.

5. Yeshiwas A, Barrie A, Peter F. 2014. A handbook for setting up and running a small-scale business producing high-value foods.

6. Dibyakanta S, Misha N. 2011. Optimazation of honey candy recipe using response surface methodology. American journal of food technology. 6: 985-993.

7. Bahiru B, Mehari T, Ashenafi M. 2001. Chemical and nutritional properties of ‘tej’, an indigenous Ethiopian honey wine: variations within and between production units. The Journal of Food Technology in Africa. 104-108.

8. Hugo P. 2016. Brewing with honey. National Honey Bad. 30-31.

9. Deborah C. 2013. Honey Gaining in Sweetener Popularity for Many Food Manufacturers.

10. Seferu T, Bhagwan S, Estifanos E. 2017. Ethanol, methanol, acid content and other quality parameters of Ethiopian traditional fermented, distilled and factory produced alcoholic beverages.

11. Glenn A, Sandra D, Barry K. 2000.Tabulation of Alcohol Content of Beer and Malt Beverages. Journal of Analytical Toxicology. 24.

12. Braide W, Azuwike O, Adeleye A. 2018. The role of microorganisms in the production of some indigenous fermented foods in Nigeria. International Journal of Advanced Research in Biological Sciences. 5: 86-94.

13. Marina VG, Elena MS, Olga AS. 2019. Methodological approaches to evaluating beer and non-alcoholic products shelf life all-Russian Scientific Research Institute of the Brewing, Non-Alcoholic and Wine Industry — Branch of the V.M. Gorbatov Federal Research Center for Food Systems of Russian Academy of Sciences, Moscow, Russia.

14. Al-Mamary M, Al-Meeri A, Al-Habori M. 2002. Antioxidant activities and total phenolics of different types of honey. Nutrition Research. 22: 1041-1047.

15. Da Silva PM, Gauche C, Gonzaga L. 2016. Honey: Chemical composition, stability and authenticity. Food Chem. 196: 309-323. Ref.: https://pubmed.ncbi.nlm.nih.gov/26593496/ DOI: https://doi.org/10.1016/j.foodchem.2015.09.051

16. Finola M, Lasagno M, Marioli J. 2007. Microbiological and chemical characterization of honeys from central Argentina. Food Chemistry. 100: 1649-1653.

17. Gupta J, Sharma R. 2009. Production technology and quality characteristics of mead and fruit-honey wines: A review. Natural product Radiance. 8: 345-355.

18. Ihekoronye A, Ngoddy P. 1985. Integrated Food Science and Technology for the tropics. Macmillan Publishers Limited, London.

19. Kücük M, Kolayli S, Karaoglu S. 2005. Biological activities and chemical composition of three honeys of different types from Anatolia. Food Chemistry. 100: 526-534.

20. Connell D, Schramm K. 1995. Mead Success: Ingredients, Processes and Techniques. 4. Zymurgy Spring. 33-39.

21. Mishra P, Verm P, Mishra S. 2011. Studies on development of ready to eat amla (Emblica officinalies) chutney and its preservation by using one preservation. AMJ Food technology. 6: 856.

22. Roldán A, van Muiswinkel, Lasanta J. 2011. Influence of pollen addition on mead elaboration: Physicochemical and sensory characteristics. Food Chem. 126: 574-582.

23. Seijo M, Escuredo O, Fernández GM. 2011. Fungal diversity in honey from northwest Spain and their relationship to the ecological origin of the product. Grana. 50: 55-62.

24. Nemo R, Bacha K. 2020. Microbial, physicochemical and proximate analysis of selected Ethiopian traditional fermented beverage. Ethiopian Journal of Science. 21: 195-205.

25. Ameha K, Biruhtesfa A, Tefera T. 2014. Cassava based food: microbial fermentation by single starter culture towards cyanide reduction, protein enrichment, and palatability,” International Food Research Journal. 21: 1751-1756.

26. Britannica. The Editors of Encyclopaedia. "Alcoholic beverage". 2008. Encyclopedia Britannica.