Indexing & Abstracting

Full Text

Review ArticleDOI Number : 10.36811/ojae.2021.110004Article Views : 0Article Downloads : 1

Critical review on use of different types of bio-diesel as sustainable fuel for Internal Combustion Engines

DB Jani

GEC, Dahod-389151, Gujarat Technological University, GTU, Gujarat, India

*Corresponding Author: DB Jani, GEC, Dahod-389151, Gujarat Technological University, GTU, Gujarat, India, Email: dbjani@rediffmail.com

Article Information

Aritcle Type: Review Article

Citation: DB Jani. 2021. Critical review on use of different types of bio-diesel as sustainable fuel for Internal Combustion Engines. Open J Archit Eng. 3: 01-07.

Copyright: This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Copyright © 2021; DB Jani

Publication history:

Received date: 30 July, 2021Accepted date: 10 August, 2021

Published date: 13 August, 2021

Abstract

World’s major transportation energy requirement cannot be met alone by use of fossil fuel based petroleum products. So, as a supplement and sustainable energy usage scope and production of bio diesel is highlighted in this article. Bio-diesel can also be the part of renewable biomass sources available freely on this planet. Use of bio diesel can be made successfully by minor modification in existing transportation vehicles easily. Still further research is going on for to overcome the limitations regarding use of bio diesel in I.C. engines like as piston ring sticking, injector chocking etc. due to its high viscosity. The present work focuses on use of bio diesel in terms of its performance characteristics in IC Engines.

Keywords: Bio-Fuel; Diesel Engine; Vegetable Oil; Pollutants

Introduction

Renewable and alternative energy sources are becoming more demanding and necessary due to increases in crude oil prices and exhaust gas emissions due to fossil fuels throughout the world. Vegetable oils are widely used for various purposes in industry to complete its requirement for energy in different applications. Due to lower sulphur content and massive source for renewable resource makes it evitable for substantial energy production requirements for transportation vehicles. Previous test results for use of vegetable oil in transportation engines were found satisfactory. This makes it promising alternative to conventionally used fossil fuel based petroleum products. The use of biodiesel in engine usage is limited by its excessive viscosity. To overcome this problem mainly thermo-chemical treatment is provided to reduce viscosity to suit engine requirements. Chemical treatment can be further explored to methods like pyrolysis, micro emulsion, transesterification, dilution etc. Mostly use of vegetable oil in blended along with main fuel to minimal fuel processing and limited engine modification [1-3]. A variety of vegetable oils such as those from soybean, rapeseed, sunflower, jatropha - carcass, palm, and cottonseed etc. have been widely investigated for production of biodiesel. Rapeseed oil and some other vegetable oils when transformed to their methyl esters have many characteristics such as density, viscosity, energy content, and cetane number close to that of diesel. Recently non-edible oil produced from jatropha-curcass seeds has gained interest as this plant can be easily grown on wastelands [4-5].

The vegetable oil esters are practically free of sulphur and have a high cetane number generally in the range 46 to 60 depending upon the feedstock. The cetane number of methyl esters tends to be slightly lower than of ethyl or higher esters. Biodiesel from saturated feed stocks such as animal fat and recycled restaurant cooking fats will generally have a higher cetane number than the esters of oils high in poly-unsaturates such as soybean oil. Due to presence of oxygen, biodiesel have a lower calorific value than the diesel fuels [6-7]. The emission studies show that the use of biodiesel results in reduction of CO, HC and PM, but slight increase in NOx emissions. Reduction in CO emission could probably be attributed to presence of oxygen in the fuel molecule. Decomposition of biodiesel produces a variety of oxygenated hydrocarbons in addition to hydrocarbons. Response of the standard HC measurement technique, the heated flame ionization detector is different for the methyl esters than HC emission and this could be partly responsible for the difference in HC emissions between the normal diesel fuels and biodiesel. The methyl esters have a lower compressibility, which results in advance of dynamic injection timing.

Composition and Properties of Bio-Fuel

Fats and oils (lipids) consist of 95-98% triglycerides. Minor constituents present in oils include free fatty acids, mono- and diglycerides, phospholipids, tocopherols, sterols, natural colouring agents as well as more or less volatile odorous compounds. Triglycerides are composed of a glycerol molecule esterified with three similar or different fatty acid molecules.

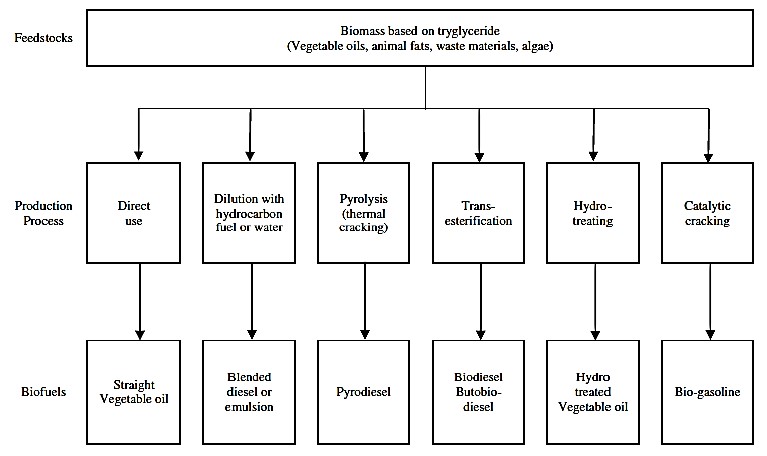

Figure 1: Production process for liquid bio-fuels from biomass feed stocks.

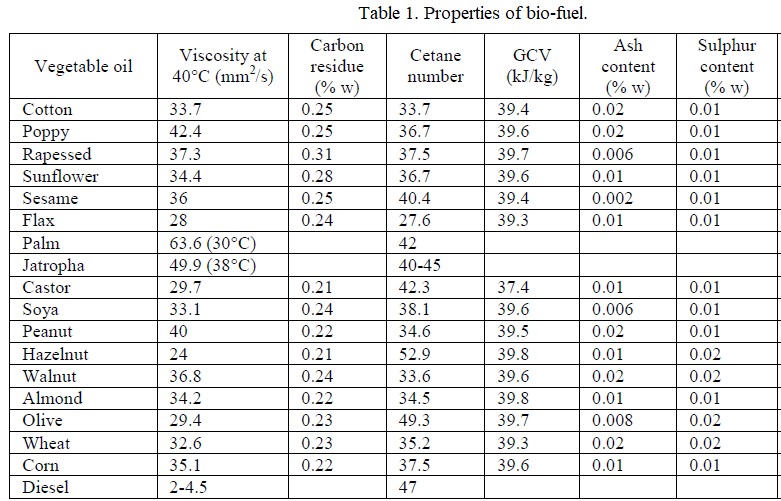

Biodiesel compared to diesel. Change in injection timing and differences in cetane number and combustion characteristics and particulate emissions are observed to be significantly lower with biodiesel compare to diesel fuels. Volumetric fuel consumption with biodiesel is higher than diesel due to its lower heating value. An increase of 10-11% in fuel consumption compared to diesel may be expected when comparing their heating values. Some twenty fatty acids are found in nature and their numerous possible combinations with the three alcohol functions of the glycerol produce a wide variety of triglycerides and therefore of oils. Generally, biomass-derived feed stocks for the production of liquid bio-fuels can be classified into the following three categories according to the source, i.e. triglyceride-based biomass, starch- and sugar-derived biomass, and cellulosic biomass. A variety of liquid bio-fuels can be produced from triglycerides based biomass such as vegetable oils, animal fats, waste cooking oils and microalgae oils as shown in Figure 1 [8-10]. Vegetable oils first developed as fuel for direct use, after more or less deep purification. The oil most frequently produced from rapeseed and sunflower, are composed of fatty acids with carbon chains (18 carbon atoms) including three chains globally longer than those of the hydrocarbons found in diesel. These oils have high molecular weights, about 0.88 kg/mole, density above 910 kg/m3, and low volatility. On heating, they generally crack at temperatures in the region of 300°C. The main characteristics of vegetable oils appear in Table 1 [11-15]. The usage of vegetable oils as diesel fuel depends on world market prices for mineral products and is therefore of special interest at present only for countries with a large excess of vegetable oil production. The measurement of density, viscosity and carbon residue is critical before using vegetable oil in transportation engine for its purity. The density of vegetable oil is ranges from 900 and 960 kg/m3 [16-18] while the viscosity of vegetable oil is much higher than conventional diesel fuel.

The high viscosity of vegetable oil causes detrimental effects like clogging injection pump, filter and fuel injector nozzle etc. resulted to lower injection rate, poor ignition property and incomplete combustion. Thermodynamic efficiency decreases drastically and also substantial increase in proportions of soot particles in the exhaust emission.

Viscosity is a rapid indicator of fuel quality before use, especially if the nature of the feedstock is not well known, or if the oil could have been deteriorated or polymerized during storage. As Figure 2 [19-20] indicates, the viscosity of pure SVO is much higher than that of diesel fuel at normal operating temperatures. This can cause premature wear of fuel pumps and injectors and can also dramatically alter the structure of the fuel spray coming out of the injectors to increase droplet size, decrease spray angle, and increase spray penetration.

Figure 2: Effect of temperature on viscosity of Sunflower oil as comparison to diesel.

Effect of Bio-Fuel on combustion

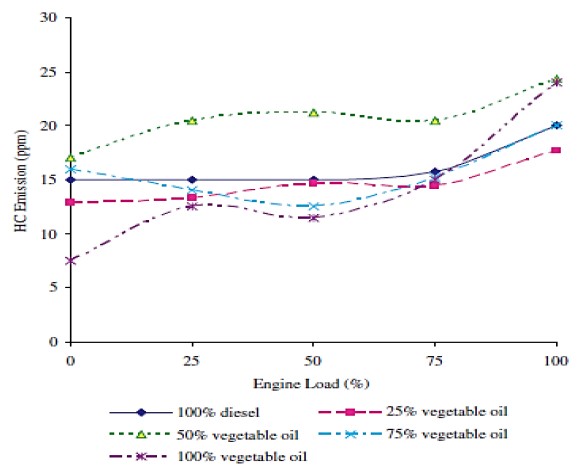

As biodiesel is produced from vegetable oils or animal fats, its use has been promoted as a means for reducing greenhouse gas CO2 emissions that would otherwise be produced from the combustion of Petroleum-based fuels. The total impact that biodiesel could have on global warming would be a function not just of its combustion products but also of the emissions associated with the full biodiesel production and consumption lifecycle. On an average the carbon content on mass basis of plant-based biodiesel is 77.8% and of animal fat based biodiesel is 76.1% compared to 86.7% for the Petroleum based diesel [21]. Since biodiesel is free from sulfur hence less sulfate emissions and particulate reduction is reported in the exhaust. Due to near absence of sulfur in biodiesel, it helps reduce the problem of acid rain due to transportation fuels. Higher thermal efficiency, lower BSFC and higher exhaust temperatures are reported for all blends of biodiesel compared to mineral diesel Biodiesel is oxygenated fuel (hence more complete combustion) and causes lesser particulate formation and emission. This is also due to oxygenated nature of biodiesel where more oxygen is available for burning and reducing hydrocarbon emissions exhaust as shown in the Figure 3 [22].

Figure 3: Effect of bio-fuel blend on HC emission.

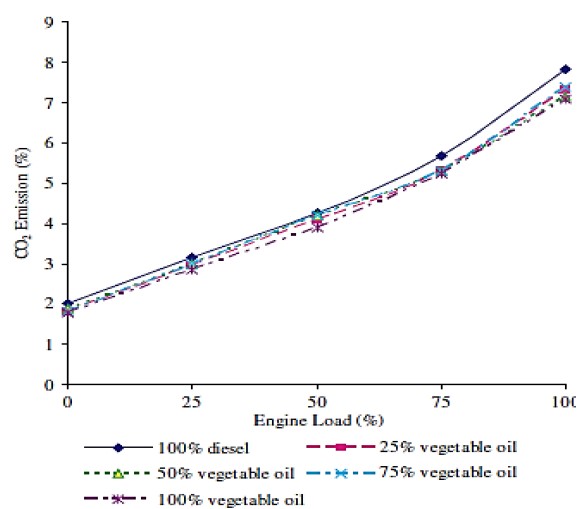

The biodiesel have a slightly higher carbon content per unit energy (2.068 kg/100MJ) than the conventional diesel (2.042 kg/100MJ) and thus may be expected to give higher CO2 emissions on combustion. The measured data however, suggest that the combustion generated CO2 from biodiesel and conventional diesel are substantially similar as shown in Figure 4 [23].

Figure 4: Effect of bio-fuel blend on CO2 emission.

The cost of vegetable oil production is much higher than the conventional fuel distillation process and refining. So, this green energy production requires substantial reduction in fuel cost taxation for to make it cost comparable against conventional fuels [24]. The production cost can be lowered further by addition of alternatives like non edible oils such as karanja, jatrpha, mahua etc. are easily available at low cost in different parts of continental places on earth. Moreover, use of waste frying oils also be a potential source of biomass for vegetable oil production in this fast food era in countries like USA, Chine, India etc. This also eliminates expenditure incurred on waste water treatment in sewerage plants and its further recycling operations too.

Conclusions

Use of vegetable oil for biodiesel production having great potential in renewable energy as plant can be growing every year. They are termed a source of green energy as it does not having harmful sulphur content in it. The main problem of using vegetable oils in diesel engines is the high viscosities of such fuels. Due to the need to adapt the combustion time, use of vegetable oils in diesel engines generally leads to higher CO, HC and PM. In contrast, due to their slower combustion and lower temperatures in the combustion chamber, vegetable oils reduce NOx emissions. While vegetable oils represent an alternative fuel, they will continue to present risks related to their intrinsic characteristics, which neither car nor agricultural tractor and machinery manufactures are willing to assume. The obtained results prove that the uses of vegetable oil as biodiesel are good alternative to conventional diesel fuel as petroleum based fossil deposits were found for the limited period.

References

1. Nigam PS, Singh A. 2011. Production of liquid biofuels from renewable resources-review. Prog Energy Combust. 37: 52-68.

2. Patel AR, Manoj G, DB Jani. 2009. Palm oil based bio-diesel as alternative bio-fuel. All India Seminar on Development of Green Fuel for Energy Security and Environmental Protection, IPS Academy, Indore. 5: 97-100.

3. Wang YD. 2006. An experimental investigation of the performance and gaseous exhaust emissions of a diesel engine using blends of a vegetable oil. Applied Thermal Engineering. 26: 1684-1691.

4. Patel AR, SM Bhatt, DB Jani. 2009. Bio-diesel as future fuel of IC engine. National Conference on Futuristic Trends in Mechanical Engineering, Parul Institute of Engineering and Technology, Baroda. 76-81.

5. Sidibe SS. 2010. Use of crude filtered vegetable oil as a fuel in diesel engines state of the art: literature review. Renew Sustain Energy Rev. 14: 2748-2759.

6. Jani DB, RM Khavdu, Twinkle P. 2010. Liquified natural gas as an automotive fuel. 2nd National Conference on Emerging Vistas of Technology in 21st Century, Parul Institute of Engineering and Technology, Baroda. 1-9.

7. Daho T. 2013. Influence of engine load and fuel droplet size on performance of a CI engine fueled with cottonseed oil and its blends with diesel fuel. Appl Energy. 111: 1046-1053.

8. Khavdu RM, DB Jani. 2011. A review of compressed natural gas as an alternative fuel for internal combustion engine. 4th National Conference on Emerging Trends in Mechanical Engineering (ETME-2011), G.H. Patel College of Engineering and Technology (G.C.E.T.), V.V. Nagar. 1-10.

9. Agarwal AK. 2007. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog Energy Combust. 33: 233-271.

10. Mewada JA, DB Jani. 2011. Bio-Ethanol and bio-diesel blends as automotive fuel for diesel engines. Gujarat Technological University Research Fair (GTU-2011), L.D.C.E., Ahmedabad. 1-7.

11. Yilmaz N, Morton B. 2011. Effects of preheating vegetable oils on performance and emission characteristics of two diesel engines. Biomass Bioenergy. 35: 2028-2033.

12. Ramadhas AS. 2004. Use of vegetable oils as IC engine fuels-a review. Renewable Energy. 29: 727-742.

13. Khavdu RM, DB Jani. 2011. CNG as an automotive fuel and its technology. National Conference on Recent Trends in Mechanical Engineering and Technology, B.V.M. Engineering College, VV Nagar. 1-8.

14. Srivastava A, Prasad R. 2000. Triglycerides-based diesel fuels. Renewable and Sustainable Energy Reviews. 4: 111-133.

15. Khavdu RM, DB Jani. 2011. Engine performance and exhaust emissions of gasoline and CNG in a retrofitted SI engine. Proceedings of 5th National Conference on Advances in Mechanical Engineering (ICAME-2011), SVNIT, Surat. 1110-1114.

16. Misra RD, Murthy MS. 2010. Straight vegetable oils usage in a compression ignition engine: a review. Renewable and Sustainable Energy Reviews. 14: 3005-3013.

17. Collerwala T, DB Jani. 2011. Effect of exhaust back pressure on engine performance by altering exhaust manifold position. Proceedings of 5th National Conference on Advances in Mechanical Engineering (ICAME-2011), SVNIT, Surat. 1-7.

18. Jani DB, Mukesh RZ, Uttam R. 2012. EGR as an NOx reduction technique in diesel fuelled IC engine - A review. Proceedings of 1st National Conference on Thermal, Fluid and Manufacturing Science (TFMS-2012), C.K. Pithawala Institute of Technology and The Institution of Engineers (India) South Gujarat Local Centre, Surat. 236-239.

19. Jani DB, Mukesh RZ, Vivek SK. 2012. Effect of EGR rate and injection timings on the performance and emissions in diesel engine - A review. National Conference on Technology and Management (NCTM-2012), Sankalchand Patel College of Engineering, Visnagar. 1-6.

20. Knothe G. 2006. Analyzing biodiesel: standards and other methods. Journal of the American Oil Chemists’ Society. 83: 823-833.

21. Hawkins CS. Engine Durability Tests with Sunflower Oil in an Indirect Injection Diesel Engine. SAE 831357.

22. De B, Panua RS. 2014. An experimental study on performance and emission characteristics of vegetable oil blends with diesel in a direct injection variable compression ignition engine. Procedia Engineering. 90: 431-438.

23. Bona S, Mosca G, Vamerli T. 1999. Oil crops for biodiesel production in Italy. Renewable Energy. 16: 1053-1056.

24. Rakopoulos CD. 2011. Comparative environmental behavior of bus engine operating on blends of diesel fuel with four straight vegetable oils of Greek origin: Sunflower, cottonseed, corn and olive. Fuel. 90: 3439-3446.