Indexing & Abstracting

Full Text

Review ArticleDOI Number : 10.36811/jca.2019.110002Article Views : 1767Article Downloads : 33

Application of Polyhedral Spherical Packing Precipitation Technology in Water Plant Reform

LI Ya wen1* Cheng Sheng gao1 and Li Ru yi2

1School of Environmental Studies Earth Sciences, China University of Geosciences, Wuhan 430074, China

2Hubei YuYang Water Engineering Co. Ltd. Wuhan 430000, China

*Corresponding author: LI Ya wen, School of Environmental Studies Earth Sciences, China University of Geosciences, Wuhan 430074, China, Email: 531738431@qq.com

Article Information

Aritcle Type: Review Article

Citation: LI Ya wen, Cheng Sheng gao, Li Ru yi. 2019. Synthesis and Characteristics of Rice Husk Ash Based Magnetic Hydrogel (RHA-MH) for H2 Generation. J Chem Appl. 1: 10-17.

Copyright: This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Copyright © 2019; LI Ya wen

Publication history:

Received date: 18 February, 2019Accepted date: 04 March, 2019

Published date: 05 March, 2019

Abstract: On the basis of micro flocculation interception sedimentation technology, polyhedral spherical packing is used as intercepting material in sedimentation tank. The process utilizes the characteristics of polyhedral sphere to make flocs and water move relatively, and continuously change the direction of water flow to produce turbulent vortices. When water moves in a vorticity, solid particles move relative to the flow along the radial direction under the action of centrifugal inertia force, which provides for the radial collision of particles with different scales along the vortices. Under these conditions, the micro flocs collide and aggregate continuously as they pass through the blades, and the concentration of alum in the water is increased. Finally, the precipitation is removed under the action of gravity. The process is applied to the reconstruction of Miluo New City Waterworks, and the original inclined pipe sedimentation tank is retained and put into operation. The results show that the turbidity of effluent from polyhedral spherical sedimentation tank can reach below 2NTU, while that from inclined tube sedimentation tank is above 2NTU. The treatment effect of polyhedral sphere on low turbidity water is better than that of inclined tube, which provides a reference for the transformation of small and medium-sized water plants in rural areas.

Keywords: Polyhedral sphere packing; Interception sedimentation; Technological transformation; Engineering application

Precipitation plays a crucial role in the water treatment process, and most water plants still use the traditional inclined tube sloping plate sedimentation tank.The inclined tube sloping plate sedimentation tank is the best practice result based on the shallow pool theory and has been applied in many aspects [1,2]. In terms of optimizing sedimentation, foreign countries have made considerable progress in this regard in recent years [3]. Representatively, it is the Densadeg high-density sedimentation tank of France's Deliman Company, the Turbo-LME high-speed sedimentation tank of Passage-Lotige, Germany, and the Actiflo high-efficiency clarification tank [4] of France Veolia. The principle is to increase the concentration of suspended solids in the coagulation process by increasing the flocculation degree of the raw water during the coagulation process, so that the scented flower is more easily removed.In addition, Yoshimasa Watanabe [5] studied the performance of jet mixing separator (JMS), combined JMS with inclined tube sedimentation tank, instead of mechanical flocculation tank and sedimentation tank, applied to rapid sand filtration. system. In view of the fact that the sedimentation tank in the actual project cannot meet the ideal sedimentation tank hypothesis, the numerical simulation technology is applied to the optimization design of the sedimentation tank. Ping Xiang [6] used computational fluid dynamics (CFD) software ANSYS Fluent to simulate the flow state of the grid flocculation tank, which provided a theoretical basis for the combination of electric flocculation and hydraulic flocculation. Zhang Ying et al. [7], summarized the research status of electro-flocculation technology in water purification.However, due to the complicated water quality situation in China and the seriousness of pollution compared with foreign countries, foreign processes have not been widely used in practical projects. Therefore, China urgently needs to propose a method to break the traditional sedimentation theory and more in line with China's water quality national conditions. Related studies have shown that there are three main reasons for the improvement of sedimentation efficiency: the increase of sedimentation area, the change of water flow state and the dynamic factor of increasing precipitation [8]. At present, the research mainly focuses on the first two points, but the third point is the most important factor affecting sedimentation. Therefore, the research on the internal force of the sedimentation tank and the actual change behavior should be the focus of future attention.

In general, most of the effluent water in the sedimentation tank is small-sized particles, which is also a difficult point of treatment. Studies have shown that after precipitated water and filtered water, particles smaller than 5μm occupy the main part [9], and these particles will cause great disturbance to drinking water quality. Moreover, the flocs in the sedimentation tank will actually undergo the process of crushing, recombination, etc. Many scholars have proposed to use the flocculation of the flocs themselves to intercept small particles [10], as summarized by Sun Hongmei et al [11]. The application of bio-filler in the treatment of micro-polluted water, Lu Chunsheng et al. [12], proposed a technique for micro-flocculation interception sedimentation tank. According to the chemical and hydrodynamic characteristics of microflocs in water, this technique uses a water-resistant, highly-adsorbed natural plant as an intercepting material to make interceptors and sedimentation tanks of specific structure and size, which realizes the adsorption collision of particles,multi-process synergy of contact condensation, aggregation and precipitation. On this basis, Wang Huasheng et al. [13], to intercept the sloping plate sedimentation tank will increase the turbidity of the effluent due to the increase of running time. After the interception of the sedimentation tank, a set of different-flow sloping plates will be added. The experimental results show that the method is effective. Guo Haiping [14] removes pollutants from sewage by utilizing the efficient interception effect of adding fillers to the traditional sedimentation tank. In summary, inspired by the interception and sedimentation technology and the proposed improvement scheme, starting from the interception material, a sedimentation process for the treatment of sewage treatment, de-sulfurization of power plants, desulfurization and water purification towers as a interceptor is proposed.

Technical characteristics

Change the direction of water flow

The polyhedral spherical packing is made of polypropylene, and a spherical body is synthesized from two hemispheres. Each hemisphere is composed of 12 semi-fan-shaped surfaces having a thickness of 1 mm, and the fan-shaped shapes of the two hemispheres are staggered from each other. It has the characteristics of large specific surface area and good mass transfer performance [15]. As shown in Figure 1.

Figure 1: SEM images of RHA-MH (a) before and (b) after hydrolysis of NaBH4.

Due to the low turbidity of the raw water, the size of the flocs formed is small, the specific gravity is close to that of water, and the movement is synchronously followed by the water flow. Without the speed difference, the flocs cannot be effectively collided, so the filler itself has multi-faceted nature and disorderly accumulation. The method can make the flocs and the water flow relatively move, and continuously change the direction of the water flow to generate a turbulent vortex, which can make the water flow resist the particles. According to the inertial effect theory [16], it is assumed that the shape of the water particles is a sphere with a radius r, the water density is the relative velocity of the particles to the water flow is F, and the hydraulic resistance of the particles is calculated as follows:

Cd is the flow resistance coefficient of the water flow.

The hydraulic resistance f of a unit mass spherical particle is:

Where is the spherical particle density. It can be seen from the formula that the hydraulic resistance f of the spherical mass per unit mass is inversely proportional to the radius r of the particle, that is, the larger the radius of the particle, the smaller the hydraulic resistance per unit mass, so the particles with different radii are different in hydraulic resistance and can generate speed. difference. When the water flows in the vortex motion, the solid particles move relative to the water flow in the radial direction under the centrifugal inertial force, which provides conditions [17] for the radial collision of the particles along different scales along the flow vortex, thereby further strengthening the treatment of the particles in the low turbid water.

In the process of flocculation and sedimentation, the flow conditions of the water flow determine the shear force of the turbulent flow, and the control of the shear force of the turbulent flow can ensure the effect of flocculation and sedimentation. The turbulent shear force is formed by the vortex of the turbulent flow. The smaller the eddy current size, the stronger the strength, that is, the stronger the shearing effect of the vortex on the flower. The degree of compaction of the flowers can be expressed by the degree of mobility e.

Where represent the pulsation velocity of the spatial point along the x, y, z

direction, and represents the average velocity of the spatial point.

Obviously, the larger the value of e, the more the number of vortices flowing through the unit space point per unit time, the greater the vortex intensity, and the denser the silk flower. Although the e value is not available in practical applications, the research direction can be invested in how to effectively increase the number of vortices in a unit space point. When the water flows through the polyhedral spherical packing, the floc particles collide with the filler to make contact and adsorb, and the speed changes fiercely. At this time, the inertial effect is the strongest, the large vortex turns into a small vortex, the quantity increases continuously, the centrifugal inertia effect is remarkable, and the formation has been formed. Because of the small volume and looseness of the raw water, the scorpion flower is strongly deformed due to the inertia of the water flow through the polyhedral spherical packing, and the deformation enthalpy action reaches a high energy-absorbing level, and the flower becomes more Compact and compact. Part of the floc is removed due to gravity sedimentation under the action of hydraulic shear. Compared with the inclined tube, the polyhedral spherical packing increases the floc concentration more significantly, and the number of floc collisions also increases significantly. The particles in the water are continuously destabilized and adsorbed by the filler and are constantly being renewed.

Easy and simple to transform

The process is relatively conventional, except that the inclined tube is replaced with the polyhedral spherical packing on the basis of the inclined tube sedimentation tank, so it can be used not only for the new water plant, but also for the process upgrade and modification in the old water plant, and the operation is simple and convenient.

Engineering applications

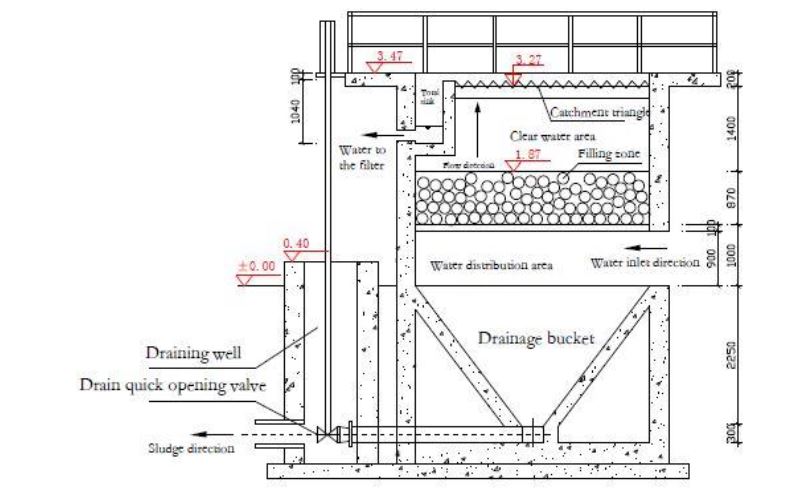

At the beginning of 2013, the water supply project in Miluo New City is to bring the water of the Lanjiadong Reservoir in Sanjiang Town into the urban area of Miluo New City, and directly supply water to users in the urban area through the established water supply facilities. through a 29.54-kilometer water pipeline, passing through Zhifeng, Changle, Patio, and Saffron. 5 townships in the new city. Among them, in the upgrading of the water plant in Miluo New City, since the raw water is taken from the Lanjiadong Reservoir, the water temperature in autumn and winter is basically 5 turbidity, so the water viscosity is large, the particle size in the water is small and the particle size distribution is uniform, and the flocculation reaction is slow, generating The sputum flower is small and difficult to settle, and the conventional filtration process cannot intercept and remove. In order to solve this problem, in addition to reforming the perforated cyclone flocculation tank, the water plant additionally added a set of polyhedral spherical packing flocculation sedimentation tanks, and retained the original inclined tube sedimentation tanks, and at the same time put into operation to form a control. Figure 2 is a physical diagram of the polyhedral spherical packing sedimentation tank.

Figure 2: Physical drawing of polyhedral spherical packing sedimentation tank.

Design parameters

The influent flow rate is the height of the water distribution area is the height of the water distribution area is 0.7-1.4m,

Process design

Design process

The height of the multi-face ball is 0.87m, the height of the catchment area is 0.6-1.0m, and the rising flow rate of the clear water area is1.94mm /s. The inlet pipe flow rate is controlled at about 1m /s.

Figure 3: Flow chart of interception and sedimentation process with polyhedral spherical packing.

Since the turbidity of raw water is basically below 10 NTU, most of them are distributed in water bodies with tiny sassafras. After the traditional process, the turbidity of the factory water cannot be reduced to below 1 NTU. The raw water is mixed with sodium hypochlorite and polyaluminum chloride pipeline, and then enters the jet and drop aeration mixing reaction. After the microflocculation of the grid, it enters the polyhedral spherical packing sedimentation tank, that is, the water distribution zone of Fig. 3, at which time the raw water has been fully destabilized and flowed. According to the polyhedral spherical packing area of Fig. 3, the squid is continuously in contact with the packing, and the squid is continuously subjected to effective collision and becomes larger, and is precipitated into the mud hopper of Fig. 2 under the action of gravity, and finally enters the mud well of Figure 3 through the pipeline; the clean water after sedimentation Through the water collecting triangle of Figure 3, it is uniformly collected into the water tank of the total collection of Figure 2 and enters the next structure filter for processing.

The water flow in thepolyhedral spherical packing forms numerous turbulent vortices of large and small turbulence. The particles in each turbulent vortex are divided into several separate detached bodies. The force of the detached body in the radial direction is divided into two types. One is centrifugal inertia. Force, the second is the combined force of pressure. Then, in a turbulent vortex, there must be a balance of the detached body with a diameter D. The centrifugal force of the detached body with diameter < D dominates the radial movement outside the vortex, and the pressure of the detached body with a diameter of >D dominates the vortex. Internal movement. It is this effect that increases the probability of radial collisions between particles of different sizes and improves the processing effect.

Precautions

Polyhedral spherical packing used for flocculation and sedimentation is still an immature water treatment process. So far there are some problems.

1. Nowadays, all the small-scale waterworks in rural areas are used, which can be used in the case of small amount of water and low turbidity. Achieving better treatment results, the processing capacity of large and medium-sized water plants and high turbidity water is still unknown, so it has limitations.

2. Polyhedral spherical packing in the process of flocculation and sedimentation, not only can intercept large particles of silk flowers, but also the small particles of sputum are adsorbed and condensed into large granules and shed. In the long run, the inside of the packing is inevitably clogged, so it is necessary to frequently flush the packing, which has an impact on the operation of the water plant.

3. Polyhedral spherical packing is used in drinking water treatment, and its material safety and non-toxicity need to be strictly guaranteed.

Operation effect

After several years of water plant transformation and operation, the raw water, polyhedral spherical packing sedimentation tank effluent and the original inclined tube sedimentation tank effluent were sampled and measured for three consecutive days in October this year. The comparison of effluent turbidity changes is shown in the Figure 4.

According to the "Standards for Sanitary Standards for Drinking Water" (GB5749-2006), the factory water turbidity requirement is ≤1NTU. According to industry standards, the effluent turbidity of the sedimentation tank should be controlled within 10 NTU, and it should be controlled within 5 NTU. The results from Figure 2 show that in the case of low turbidity of raw water turbidity of about 5 NTU, the effluent turbidity of the multi-face ball sedimentation tank is about 1 NTU lower than that of the inclined tube sedimentation tank. It can be seen that the multi-faceted sedimentation tank is low turbidity. The raw water treatment effect is better than the inclined tube sedimentation tank.

Conclusion

(1) The removal of particulate matter by the multi-face ball filler mainly forms a vortex by continuously changing the direction of the water flow, which increases the effective collision of the silk flower, makes the silk flower become dense and is beneficial to the sedimentation effect.

(2) According to the actual effluent turbidity, the turbidity of the water after the sinking of the multi-faceted sedimentation tank is 1 NTU lower than that of the inclined tube sedimentation tank, indicating that the multi-faceted ball filler is slightly better than the inclined tube for the treatment of low turbidity water. However, whether the multi-face ball filler has a good treatment effect on medium and high turbidity water needs further study.

(3) The process is simple and cost-saving, and can be used for the construction and renovation of new and old water plants.

References

- Tian Linqing, Zhang Yafang, Peng Zhaoxu. 2017. Operation and optimization of a new type of co-current inclined plate sedimentation tank device[J]. Journal of Harbin University of Commerce (Natural Science Edition). 33: 530-536. [Ref.]

- Li Xinping, Sun Liyun, Zhang Wei. 2018. Experimental study on treatment of high turbidity and micro-polluted water by inclined plate sedimentation tank[J]. Henan Science and Technology. 11: 139-141.[Ref.]

- Lu You, Li Xing, Yu Wei. 2012. Typical high efficiency coagulation and sedimentation process [J]. Water purification technology. 31: 38-41. [Ref.]

- Luo Qida, Zhou Keming, Chen Wei. 2004. ACTIFLO-A New Efficient Water Treatment Clarification Process[J]. Water Purification Technology. 1: 38-41.[Ref.]

- Yoshimasa Watanabe, Shinsuke Kasahara, Yoshihiko Iwasaki. 1998. Enhanced flocculation/sedimentation process by a jet mixed separator. Water Sci Technol. 37: 55–67. [Ref.]

- Ping Xiang, Yihui Wan, Xun Wang, et al. 2018. Numerical simulation and experimental study of electrocoagulation grid flocculation tank. Water Sci Technol. 78: 786-794. [Ref.]

- Zhang Ying, Gong Taishi. 2009. Application and Development of Electroflocculation Technology[J]. Safety and Environmental Engineering. 16: 38-40.[Ref.]

- Wang Huasheng, Liu Zuwen. 2004. Research Status and Development Trend of Precipitation Process[J]. Copper Engineering. 54-56.[Ref.]

- Hu Panpan. 2011. Analysis of morphological characteristics and control technology of floc particles in microflocculation stage. [Ref.]

- Jiang Xia. 2013. Study on the enhancement of water treatment and sedimentation process and the adaptability of water quantity change. [Ref.]

- Sun Hongmei, Yang Xiaoli, Lu Jilai. 2008. Application of Biofillers in Micro-polluted Water Treatment [J]. Safety and Environmental Engineering.15: 55-59.[Ref.]

- Lu Chunsheng, Qu Jiuhui, Li Dapeng. 2000. Microflocculation interception and sedimentation treatment of low temperature and low turbidity water [J]. China Water Supply and Drainage. 9-13. [Ref.]

- Wang Huasheng, Liu Zuwen, Pei Changfu. 2004. Study on the technology of intercepting inclined plate settlement[J]. Water Purification Technology. 12-13.[Ref.]

- Guo Haiping. 2010. Experimental study on municipal wastewater treatment by adding sediment and strengthening sedimentation [D]. Qingdao Technological University.[Ref.]

- Mo Xirong, Jiang Shengnan, Feng Yu. 1981. Hydrodynamics and mass transfer performance of multi-face ball fillers [J]. Journal of Beijing Institute of Chemical Technology. 3: 112-121.[Ref.]

- Meng Rongguo. 2007. Dynamics effect of inertial effect in coagulation[J]. Science and Technology Information (Science and technology teaching and research).[Ref.]

- Wang Shaowen. 1998. Kinetics of inertial effect in flocculation [J]. China Water Supply and Drainage. 2: 13-16.[Ref.]