Indexing & Abstracting

Full Text

Research ArticleDOI Number : 10.36811/ijme.2021.110005Article Views : 2Article Downloads : 3

Use of artificial neural network in performance prediction of Solid desiccant powered Vapor compression air conditioning systems

Jani DB

Gujarat Technology University GTU, Ahmedabad, India

*Corresponding Author: Jani DB, Gujarat Technological University, GTU, Ahmedabad, India, Tel: +91-9428044640; Email: dbjani@rediffmail.com

Article Information

Aritcle Type: Research Article

Citation: Jani DB. 2021. Use of artificial neural network in performance prediction of Solid desiccant powered Vapor compression air conditioning systems. I J Mech Eng. 3: 05-19.

Copyright: This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Copyright © 2021; Jani DB

Publication history:

Received date: 22 February, 2021Accepted date: 03 March, 2021

Published date: 05 March, 2021

Abstract

In the present study, artificial neural network (ANN) model for a solid desiccant-vapor compression hybrid air-conditioning system is developed to predict the cooling capacity, power input and coefficient of performance (COP) of the system. This paper also describes the experimental test set up for collecting the required experimental test data. The experimental measurements are taken at steady state conditions while varying the input parameters like air stream flow rates and regeneration temperature. Most of the experimental test data (80%) are used for training the ANN model while remaining (20%) are used for the testing of ANN model. Experimental data were collected during cooling period of March to September. The outputs predicted from the ANN model have a high coefficient of correlation (R>0.988) in predicting the system performance. The results show that the ANN model can be applied successfully and can provide high accuracy and reliability for predicting the performance of the hybrid desiccant cooling systems.

Keywords: Artificial neural network; Coefficient of performance; Dehumidifier effectiveness; Moisture removal rate, TRNSYS

Introduction

Integration of the desiccant dehumidification system with traditional vapor compression refrigeration (VCR) air-conditioning system results in hybrid cooling system which efficiently meets both the sensible and latent cooling loads by handling them separately. VCR system operates at higher evaporator temperature, requires no post heating that resulting in higher performance of the system. The desiccant cooling systems are very good at providing comfort cooling by reducing the humidity ratio of air. Moreover, hybrid desiccant cooling systems limit the use of chlorofluorocarbons (CFCs) as the size of VCR cooling unit gets reduced by handling the latent heat load separately. Desiccant cooling systems also allow larger flow rates of ventilation air to improve indoor air quality by removing air borne pollutants. The desiccant cooling system can be cost effective, when used with renewable (solar) or waste heat for regeneration. It also avoids microbial growth in ducting by the use of dry cooling coils. Desiccant cooling are used in several applications such as pharmaceutical plants, supermarkets, theatres, hotels, office buildings, hospitals, health clubs and swimming pools. Different configurations of desiccant cooling system have been proposed by many investigators so far to attain higher system performance. The earliest form of desiccant cooling cycle was proposed by coupling dehumidifier with heat source and evaporative cooler [1]. Similar cycle was proposed by Dunkle [2] using dehumidifier of molecular sieve with additional heat exchanger to achieve the better performance than the earlier one. Later on, Munter [3] further enhanced the performance of the desiccant cooling cycle by introducing parallel passages in dehumidifier and provided backup of vapor compression system to tackle the cooling load. Since then, number of efforts has been made for the performance evaluation of rotary desiccant dehumidifiers used in the desiccant cooling systems. Important among those were the analogy theory by Banks [4], the pseudo-steady state model by Barlow [5], combined potential technique by Jurinak [6], finite difference method for cross-cooled dehumidifiers [7] and finite difference method by Maclaine-Cross [8] which are now widely used by other researchers in getting better performance of desiccant cooling cycles [9]. Burns et al. [10] evaluated the performance of hybrid desiccant cooling cycle used for supermarket and shows better performance than conventional VCR system [11-17]. From literature review [18-27], one can observe that some researchers developed mathematical models for evaluating the performance of desiccant cooling system while others conducted expensive experimental studies. The mathematical approach requires a large number of parameters defining the system, which may not be readily available and their predictions may not be sufficiently accurate in many cases [28-34]. As an alternative, use of artificial neural networks (ANNs) requires less effort, time and cost to model the system. This new modelling technique is used in many engineering applications, where classical approaches are too complex to be used. So, ANNs allow modelling of physical phenomena in complex systems without requiring explicit mathematical representations or without requiring exhaustive experiments. ANNs can predict the desired output of a system when enough experimental is data available.

System Description

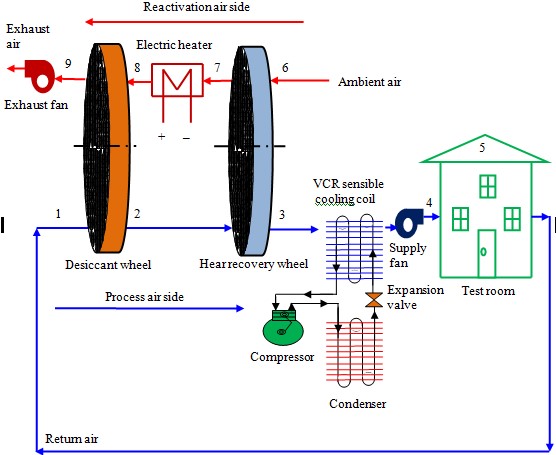

A test room having dimensions 3m × 3m × 3m, has been selected for the study. The sensible and the latent cooling loads are taken as 1.371 kW and 0.391 kW, respectively. Sensible heat ratio (SHR) has been obtained as 0.78. Flow rates of the process air stream and the regeneration air stream are measured as 322.7 m3/hr and 196.8 m3/hr respectively. The comfort conditions are taken as 50% relative humidity and 26°C dry bulb temperature. The schematic diagram and the photographic view of solid desiccant and vapor compression hybrid air-conditioning system have been shown in figure 1. The return room air at state 1 passes through the rotary desiccant dehumidifier. Its moisture is adsorbed significantly by the desiccant material and the heat of adsorption raises its temperature up to state 2. The hot and dry air is first sensibly cooled in an air-to-air heat exchanger (2-3) and then in cooling coil of VCR system up to state 4. In the regeneration airline, ambient air at state 6 enters the air-to-air sensible heat exchanger and cools the supply process air. Consequently, its temperature rises when exiting from sensible heat exchanger at state 7. At this point, it is heated to reach temperature at the state point 8 which is high enough to regenerate the desiccant material. Moist air at the outlet of dehumidifier is exhausted to atmosphere at state 9. The rotary desiccant dehumidifier used is 360 mm diameter and 100 mm width. Rotational speed of the dehumidifier is kept constant as 20 rph. Synthesized metal silicate is the desiccant material used in desiccant wheel [35-37].

Figure 1: Schematic diagram of solid desiccant - VCR hybrid air-conditioning system.