Indexing & Abstracting

Full Text

Review ArticleDOI Number : 10.36811/ijme.2019.110001Article Views : 27Article Downloads : 19

Desiccant cooling as an alternative to traditional air conditioners in green cooling technology

Jani DB

Gujarat Technological University, GTU, Ahmedabad, India

*Corresponding Author: Jani DB, Gujarat Technological University, GTU, Ahmedabad, India, Email: dbjani@rediffmail.com

Article Information

Aritcle Type: Review Article

Citation: Jani DB. 2019. Desiccant cooling as an alternative to traditional air conditioners in green cooling technology. I J Mech Eng. 1: 01-13.

Copyright: This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited. Copyright © 2019; Jani DB

Publication history:

Received date: 25 November, 2019Accepted date: 06 December, 2019

Published date: 09 December, 2019

Abstract

Desiccant-based dehumidification and air conditioning systems are considered as an energy efficient alternative to traditional vapor compression based air-conditioning systems for green building cooling technology especially in tropical hot and humid ambient climates. It is a novel green cooling technology that makes use of low-grade heat for building air conditioning. It is seen that the desiccant based dehumidification and cooling can efficiently provide comfort conditions in subtropical and especially hot and humid tropical climates. The desiccant integrated novel cooling system has a significant higher coefficient of performance compared to the conventional vapor compression system resulting to substantial electrical energy savings during the summer season by use of renewable solar energy, which also resulted in to major reduction in CO2 emissions. Therefore, these results demonstrate that there is a good potential in desiccant-based dehumidification and cooling system for energy and carbon savings while carry out building air-conditioning. Through a literature review, the feasibility of the desiccant assisted air conditioning in hot and humid climatic conditions is proven and the advantages it can offer in terms energy and cost savings are underscored.

Keywords: Air-conditioning; Desiccant cooling; Dehumidification; Green cooling; Thermal comfort

Introduction

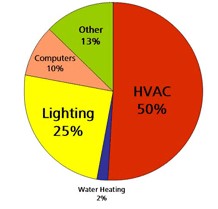

Residential and commercial buildings are responsible for about 43% of the total energy consumption in the world in the present time, and almost 50% of this energy consumption is resulted by different HVAC (heating, ventilating and air-conditioning) systems as shown in figure 1 [62]. This value may increase substantially for tropical and humid climate and may reach up to 70% of total power consumption of buildings for specific applications. The situation is worse in part where the humid climates in which an air conditioning system must reduce the air humidity in addition to reducing its temperature. For instance, the typical place may with an extremely hot and humid climate, 80% of this electricity consumption is used by dehumidification and cooling systems to preserve the products in commercial use and thermal comfort in residential applications. Nowadays, air conditioning in hot and humid climates are mostly done by traditionally used vapor compression cooling systems. Dehumidification in these systems is done by reducing the air temperature by cooling it below its dew point. The resulted air is too cold to be directly supplied to the home. So, it requires to be heated again, resulting in a thermodynamically inefficient process and large amount of electricity consumption. Moreover, the extensive use of these systems has led to increase in CFC (chloro fluoro carbon) levels and depletion of the ozone layer. In the last few years, desiccant-based cooling systems have been widely studied as an attractive alternative to vapor compression systems. In these systems, the sensible and latent loads are controlled independently. Also, the latent heat is reduced without cooling the air below its dew point, which is a great advantage over vapor compression cooling systems, and also reduces condensation issues in humid regions. Furthermore, they provide some other merits over traditional cooling such as indoor air quality improvement, carbon emissions reduction and electrical power savings.

Figure 1: Energy consumption by the different applications in a commercial building.

A first attempt of developing desiccant-based dehumidification integrated cooling systems was begun with proposing different cycles. Pennington [1] developed the first desiccant-dehumidification based cooling cycle, which is already known as Pennington cycle. Pennington cycle was an open cycle using 100% outside air. Recirculation cycle was proposed as a modified version of Pennington cycle with 100% use of return air [2]. Many other modified cycles were then developed for enhancing the performance of desiccant-based cooling systems such as Dunkle cycle [3], SENS cycle [4], REVERS cycle [5] and DINC cycle [6]. These cycles are now the base of many different configurations designed for desiccant-based systems.

Present investigations on desiccant-based dehumidification and cooling systems is mainly focused on exploring more energy-efficient configurations using renewable and waste heat energy sources for desiccant reactivation. To this aim, many investigators have evaluated the integration of traditional cooling systems such as evaporative cooling or vapor compression systems with desiccant-based cycles to improve their performance and increase their climatic applicability especially in hot and humid climate. A common approach is the combination of vapor compression systems with desiccant-based cycles which are known as hybrid desiccant-based cooling systems downsize the size of traditional vapor compression unit for the same capacity. As the latest researches in this approach, Jani et al. [7] developed novel desiccant-based hybrid cooling system to simulate as well as experimentally measuring performance of a hybrid cooling system combining solid desiccant wheel with a traditional vapor compression system. Results show the good performance and potential energy saving of the proposed hybrid cycle with substantial reduction in cooling energy supply. Nie et al. [8] proposed test unit to experimentally investigate the combination of desiccant wheel and typical heat pump cycle. Results prove higher cooling efficiency of the proposed desiccant dehumidification integrated hybrid cooling system over a conventional cooling and dehumidifying system. Hwang et al. [9] measured the potential amelioration in cooling performance of a hybrid solid desiccant integrated dehumidification and cooling system by replacing a sensible heat recovery wheel of this system with a heat pump. It is seen that with the optimal heat pump capacity, the total energy consumption reduces by 25% and the cooling capacity increases by 48% as compared to the traditional HVAC system. Shen and Abu-Heiba [10] developed a hybrid HVAC system by integrating the gas engine-driven heat pump and a desiccant dehumidifier. In this system, waste heat of gas engine is recovered to provide regeneration heat of the desiccant wheel and to augment coefficient of performance of the cooling system. An overall COP (coefficient of performance) is found more than 1.47 was reported for this system. Liu et al. [11] studied desiccant wheel integrated CO2 heat pump, in which the waste heat of heat pump gas cooler is utilized for desiccant wheel reactivation. It is found that the desiccant assisted hybrid cooling system can provide an energy saving of about 35-40% as compared to the traditional HVAC system. Another common systems which are usually combined with desiccant-based dehumidification cycles are indirect evaporative coolers. Major intensive of using these systems is that unlike the recurrent cycle, they consume little energy and, unlike direct evaporative coolers, do not increase the humidity of the supply air. As the most recent researches in this approach, Comino et al. [12] measured the annual energy saving potential of a desiccant-based indirect evaporative cooling system with respect to a direct expansion cooling system for various ambient outdoor conditions. It was seen that the proposed hybrid cooling system could achieve a substantial energy saving up to 48%. Pacak et al. [13] experimentally investigated the performance of the solid desiccant dehumidification assisted hybrid cooling system with two different indirect evaporative coolers, namely a regenerative Maisotsenko Cycle and a cross-flow Maisotsenko Cycle, and evaluated the impact of operating conditions on their performance. It was seen that a cross-flow Maisotsenko Cycle provides better cooling capacities and is more sensitive to variations of outdoor climate. The necessary heat required for the desiccant reactivation responsible for major share of their overall electrical energy consumption of the system. Consequently, another common approach to rise the energy efficiency of these systems is utilizing free energy sources like as renewable solar energy or industrial waste heat for regeneration. Angrisani et al. [14] integrated a desiccant-based heating and cooling system with a novel heating and cooling system based on the coupling between a low or medium-enthalpy geothermal source. Heidari et al. [15] developed a desiccant based novel cooling and dehumidifying system utilizing flare stack waste. Dynamic hourly simulations were performed for the hot and humid tropical climate. Another interesting energy source for regeneration is a renewable solar energy, which its highest amount is coincident with the peak of cooling demand during the summer time. As the most recent papers, Chaudhary et al. [16] developed a solar assisted desiccant-based hybrid cooling system in which Maisotsenko cycle having indirect evaporative cooling system is integrated with solid desiccant dehumidifier and evacuated tube solar collectors are used for providing the necessary reactivation heat for the desiccant regeneration. Frein et al. [17] studied solar assisted desiccant-based dehumidification and hybrid cooling system coupling the solid desiccant dehumidifier, indirect evaporative cooler and a heat pump system. The merits and limitations of this novel cooling system have been compared to a traditional cooling unit and the results were also reported. It was found that the hybrid desiccant-based cooling system provide high air quality while it has simpler control process and lesser energy consumption as compared to the traditional air conditioning unit. Although desiccant-based cooling systems offer many merits over conventional vapor compression systems, but there are many limitations were found regarding their requirement for the high regeneration energy [18], high investment cost, difficult control and poor dynamic properties [19]. A very common method for cooling production in desiccant-based systems is evaporative cooling. It has resulted to high water consumption of these systems in hot regions, which is another major drawback of them. Today, water is a restricted resource [20], and a key environmental concern [21]. Developing a cooling system to save both energy and water will be an important step to achieve a more sustainable cooling method. To this aim, this study review desiccant-based evaporative cooling systems which can makes use of renewable solar energy for desiccant regeneration.

Main objectives of this study are to:

• Investigate the system capability in providing indoor thermal comfort in extremely hot and humid tropical climate;

• Explore its potential energy saving over a conventional cooling and dehumidifying system;

Description of the system

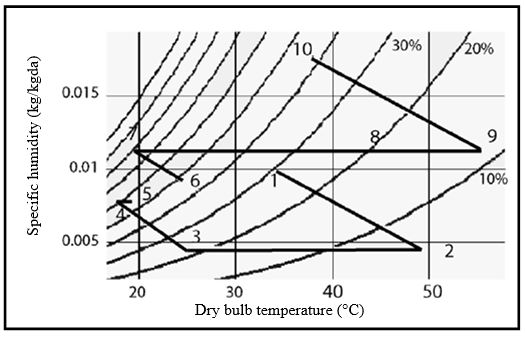

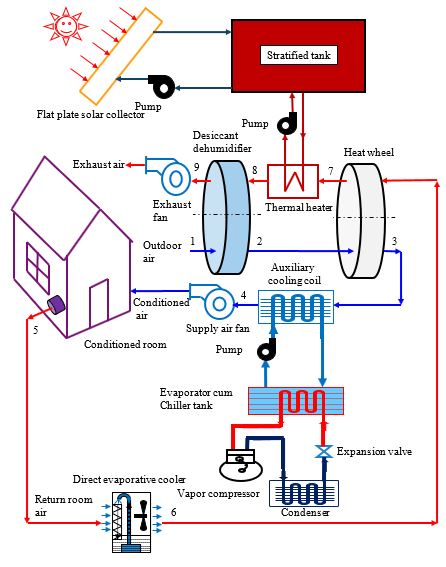

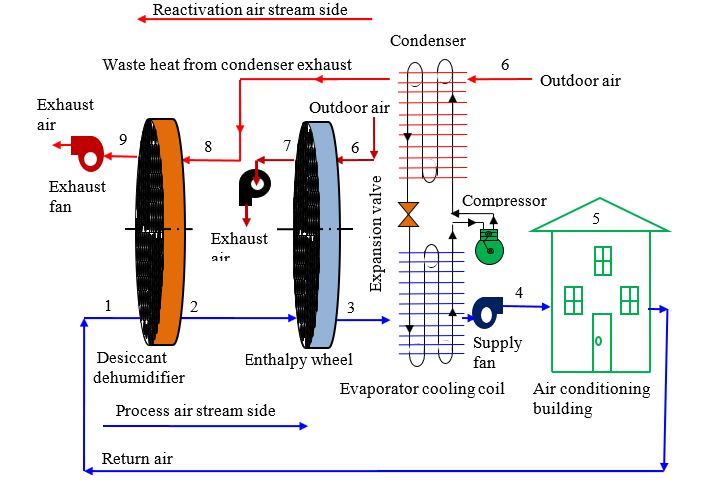

The detailed construction of desiccant assisted dehumidification and cooling system described by use of schematic chart in figure 2. The ambient air first passes through the rotary desiccant dehumidifier where its moisture is absorbed (state point 1-2). This air then enters into a hybrid cooling system. Then it pass through sensible heat recovery wheel to reduced its temperature sensibly (state point 2-3) by reverse flow of colder room air (state point 7-8) by passing through evaporative cooler (state point 6-7) in regeneration air side. The desiccant assisted hybrid cooling system is consisted of a modified evaporative cooler which is designed to cool the air (state point 3-4). The resulted dry and cool conditioned process air is then supplied to the room. For continuous operation of desiccant wheel, the absorbed moisture should be removed continuously. To this aim, a hot air, called reactivation air, passes through the rotary desiccant dehumidifier and evaporates its moisture content (state point 9-10). The desiccant wheel continuously rotates between supply air and regeneration air ducts, removing moisture from supply air and discharging it into regeneration air. The regeneration air then passes through the desiccant wheel and removes the absorbed moisture. The regeneration heat necessary for the desiccant desorption (state 9-10) is provided by the flat plate solar collector via thermal heater (state 8-9) [22-23].

Figure 2: Schematic layout of desiccant assisted dehumidification and cooling system.

The adsorption as well as desorption processes are adiabatic in nature but the wave propagation effect during the reactivation process of the desiccant wheel used in the desiccant assisted hybrid cooling system would make slight deviation from the theoretical process. Heat supply from the primary energy is the first choice for desiccant regeneration heat supply to lower high-grade electrical energy consumption. Since it can be used to reduce overall energy requirement by the use of the desiccant dehumidification and cooling system without the need of maintenance of low temperature for removing moisture from the outdoor air. Furthermore, use of renewable solar energy is found most suitable as the cooling load profile is in-line with the existence of the intensive solar radiations during the same time. The air-to-air heat recovery unit is used to conserve the sensible heat and pre-cool the ambient air. Two evaporative coolers of direct contact types are providing in both the process air side as well as the regeneration air side each to control the supply humidity. The direct evaporative cooler provided in supply air line to cool down the supply air up to the humidity level capable of tackling the space latent load. Another direct contact type evaporative cooler is installed to cool down the return room air, for furnishing better sensible heat extraction at the air-to-air heat recovery wheel figure 3, [24-26].

Figure 3: Psychrometric chart representation of desiccant assisted hybrid cooling system.

Different techniques for desiccant regeneration

Desiccant regeneration with renewable solar energy

The major drawback of the desiccant assisted cooling is as described above is the demand for large regeneration heat supply for desorption of the saturated desiccant during part of its rotation cycle. If this heat can be supplied from the freely available from the renewable energy source like as solar heat then the system has become economically viable. Moreover, the demand of cooling increases in line with the availability of sun radiations during the same period. The desiccant is reactivated by the thermal heat produced by renewable solar thermal energy with different types of solar collectors as shown in figure 4. An auxiliary heater is used when the solar radiations are insufficient to produce the required regeneration heat due to winter or cloudy seasonal conditions. Regenerating the desiccant wheel by use of solar energy is an interesting option to converge the cooling demands of space cooling as the available solar intensity is found highest during the same period [27-30].

Figure 4: Supply of regeneration heat by use of renewable solar energy in desiccant cooling system.

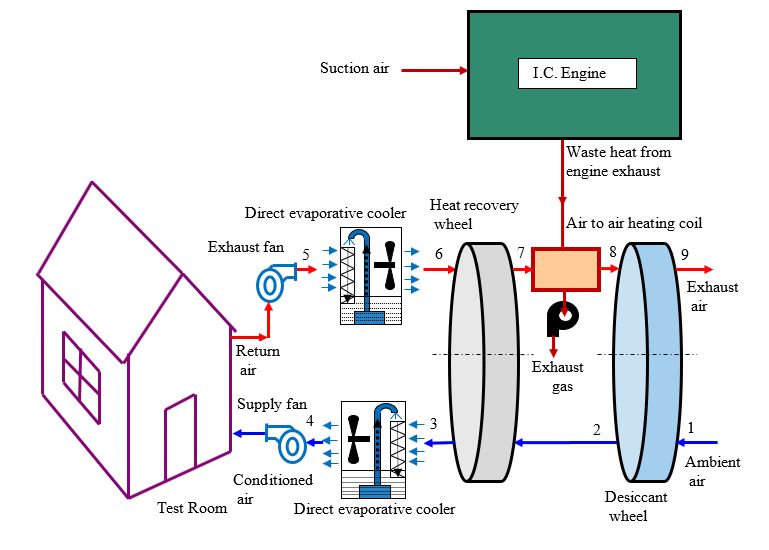

Desiccant regeneration with industrial waste heat

The desiccant wheel used in the desiccant integrated hybrid cooling system can be regenerated with help of either the exhaust of internal combustion engine of large diesel generator set or industrial waste process heat as shown in figure 5. By this way dual advantage can be obtained first the amelioration in the dehumidification capacity of the dehumidifier used in the desiccant cooling system at the same time secondly it recover the waste heat otherwise dissipated directly to the atmosphere as exhaust. This also reduces the operating cost of the dehumidifier. With this combination the overall efficiency of both the engine as well as cooling system both increases simultaneously. Furthermore, the efforts are still needed to develop advanced desiccant materials which are possibly got reactivated near the ambient temperature which is comparatively lower and so that it can be taken up the low temperature industrial waste heat. This also offered benefit in system COP of the desiccant assisted hybrid cooling system as compared to that of the vapor compression based traditional cooling system [31-34].

Figure 5: Supply of regeneration heat by use of industrial waste heat in desiccant cooling system.

Desiccant regeneration with condenser heat

The desiccant used in rotary dehumidifier may also gets regenerated by use of heat recovery carried out waste heat expelled by the VCR (vapor compression refrigeration) condenser as shown in figure 6. This result into amelioration of cooling performance of solid desiccant-based hybrid comfort space cooling system as well as efficient cooling of the condenser [35-37]. Thus, reactivation heat requirement of dehumidifier used in solid desiccant-based vapor compression integrated hybrid cooling can also be provided by use of VCR condenser exhaust heat otherwise it is expelled to open atmosphere. This proves that the utilization of waste heat for dehumidifier reactivation not only achieves better energy savings but also marginal reduction in running cost of the system which results into economical feasibility of the system [38-40].

Figure 6: Supply of regeneration heat by VCR condenser exhaust heat in desiccant cooling system.

Performance comparison of desiccant cooling with conventional VCR cooling

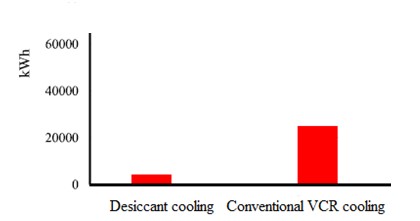

The comparison between desiccant cooling and conventional VCR cooling for electrical energy utilization has been depicted in figure 7. To provide a more tangible comparison, the hourly electricity consumption of desiccant dehumidification integrated cooling system and conventional vapor compression cooling system are integrated over the entire summer cooling season for tropical hot and humid climate [41-45]. Using desiccant dehumidification and cooling system, substantial reduction in electrical energy consumption could be obtained as compared to the conventional vapor compression cooling system. Thus, results provide fascinating insight into the significant energy saving potential of desiccant dehumidification and cooling system in a tropical and subtropical humid climate [46-50].

Figure 7: Comparison between desiccant cooling system and conventional VCR cooling system for electrical energy consumption.

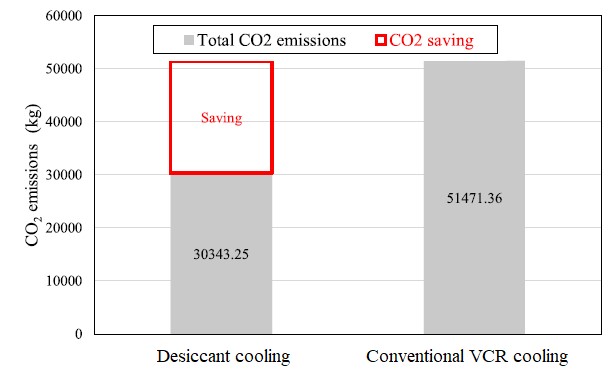

Space heating and cooling also plays an important role in building sector energy consumption and environmental impacts [51-55]. To evaluate the carbon saving potential, total carbon dioxide emissions of desiccant dehumidification and cooling system and conventional vapor compression cooling system over the summer cooling season are shown in figure 8. The carbon emission of each energy carrier is the sum of on-site and off-site emissions [56-57]. Using the desiccant dehumidification and cooling system will preserve substantial CO2 emissions during the summer cooling season. These results indicate that the desiccant dehumidification and cooling system could significantly reduce the CO2 emissions of space cooling in the tropical and subtropical hot and humid climate, providing a more sustainable cooling method [58-61].

Figure 8: Comparison between desiccant cooling system and conventional VCR cooling system for CO2 emissions saving.

Conclusions

The present study summarizes use of desiccant dehumidification system in modern air conditioning in energy saving and green cooling approach in building comfort cooling. Desiccant based hybrid cooling systems can achieve substantial energy savings by use of freely available solar energy or waste heat from industrial processes for reactivation of desiccant material used in rotary dehumidifiers used in the system to make the hybrid cooling system more cost effective. It can also help to alleviate the peak supply of electrical power demanded by the conventional vapor compression air conditioning system required during the hot sunny days by use of renewable solar energy. Future innovations in the type of desiccant materials which get regenerated at lower reactivation temperature by making use of available low temperature waste will augmenting the contribution of desiccant cooling which can bring to the amelioration of comfort, energy and cost savings.

Further improvement in energy utilization rate, reduction in cost and size, competitive design and production are the key factors to be faced by desiccant assisted modern air conditioning techniques for obtaining more extensive acceptability in the field of space cooling.

Nomenclature

COP Coefficient of performance

RH Relative humidity (%)

R/P Regeneration air flow/process air flow

T Dry bulb temperature (°C)

V Flow rate of air stream (m3/hr)

VCR Vapor compression refrigeration

Subscripts

0 Dead state

1,2, etc. State numbers

CC Cooling coil

EC Evaporative cooler

DW Desiccant wheel

h heat source

HRW Heat recovery wheel

p Process air

r Regeneration air

References

1. Pennington NA. 1955. Humidity changer for air-conditioning. Google Patents.

2. Jain S, Dhar P, Kaushik S. 1995. Evaluation of solid-desiccant-based evaporative cooling cycles for typical hot and humid climates. Int J Refrig. 18: 287-296. Ref.: https://bit.ly/2rUC7S0

3. Collier R, Arnold F, Barlow R. 1981. Overview of Open-Cycle Desiccant Cooling Systems and Materials. Golden, CO: National Renewable Energy Laboratory (NREL).

4. Pesaran AA, Penney TR, Czanderna AW. 1992. Desiccant cooling: state-of-the-art assessment Golden, CO (United States): National Renewable Energy Lab.

5. La D, Dai YJ, Li Y, et al. 2010. Technical development of rotary desiccant dehumidification and air conditioning: a review. Renew Sustain Energy Rev. 14: 130-147. Ref.: https://bit.ly/2sLvO3X

6. Nie J, Zan Li, Wenju Hu, et al. 2017. Theoretical modelling and experimental study of air thermal conditioning process of a heat pump assisted solid desiccant cooling system. Energy Build. 153: 31-40. Ref.: https://bit.ly/34Pyg7t

7. Jani DB, Mishra M, Sahoo PK. 2016. Experimental investigation on solid desiccant - vapor compression hybrid air- conditioning system in hot and humid weather. Applied Thermal Engineering. 104: 556-564. Ref.: https://bit.ly/35XsPUf

8. Nie J, Zan Li, Wenju Hu, et al. 2017. Theoretical modelling and experimental study of air thermal conditioning process of a heat pump assisted solid desiccant cooling system. Energy Build. 153: 31-40. Ref.: https://bit.ly/2Ymlfju

9. Hwang WB, Choi S, Lee DY. 2017. In-depth analysis of the performance of hybrid desiccant cooling system incorporated with an electric heat pump. Energy. 118: 324-332. Ref.: https://bit.ly/385ybib

10. Shen B, Abu-Heiba A. 2017. Gas engine-driven heat pump with desiccant dehumidification Oak Ridge, TN (United States): Oak Ridge National Lab. (ORNL).

11. Liu Y, Meng D, Sun Y. 2017. Feasible study on desiccant wheel with CO2 heat pump. IOP Conference Series: Earth and Environmental Science. IOP Publishing.

12. Montilla FC. 2017. Experimental and numerical study on hybrid HVAC systems activated at low temperature based on desiccant wheels and indirect evaporative coolers. Córdoba: Universidad de.

13. Pacak A, et al. 2018. Impact of indirect evaporative air cooler type on the performance of desiccant systems. E3S Web of Conferences. EDP Sciences.

14. Angrisani G, et al. 2016. Design of a novel geothermal heating and cooling system: Energy and economic analysis. Energy Convers Manage. 108: 144-159. Ref.: https://bit.ly/2sJ5zuR

15. Heidari A, et al. 2018. Innovative desiccant-based evaporative cooling system using flare gas heat recovery. In: 12th International Energy Conference. Tehran, Iran.

16. Chaudhary GQ, et al. 2018. Integration of solar assisted solid desiccant cooling system with efficient evaporative cooling technique for separate load handling. Appl Therm Eng.

17. Frein A, et al. 2018. Field testing of a novel hybrid solar assisted desiccant evaporative cooling system coupled with a vapour compression heat pump. Appl Therm Eng. 130: 830-846.

18. Jani DB, Mishra M, Sahoo PK. 2016. Solid desiccant air conditioning - A state of the art review. Renewable and Sustainable Energy Reviews. 60:1451-1469. Ref.: https://bit.ly/2rWB6J7

19. Jani DB, Mishra M, Sahoo PK. 2017. A critical review on solid desiccant-based hybrid cooling systems. International Journal of Air-conditioning and Refrigeration. 25: 1-10. Ref.: https://bit.ly/2YfXGJ9

20. Jani DB, Mishra M, Sahoo PK. 2018. A critical review on application of solar energy as renewable regeneration heat source in solid desiccant - vapor compression hybrid cooling system. Journal of Building Engineering. 18: 107-124. Ref.: https://bit.ly/2sJ5HKR

21. Jani DB, Mishra M, Sahoo PK. 2018. Investigations on effect of operational conditions on performance of solid desiccant-based hybrid cooling system in hot and humid climate. Thermal Science and Engineering Progress. 7: 76-86. Ref.: https://bit.ly/2Yfuu4J

22. Daou K, Wang RZ, Xia ZZ. 2006. Desiccant cooling air conditioning: a review. Renew Sustain Energy Rev. 10: 55-77. Ref.: https://bit.ly/2DK1rgm

23. Van den Bulck E, Mitchell JW, Klein SA, 1986. The use of dehumidifiers in desiccant cooling and dehumidification systems. Transactions of ASME. 108: 684-691. Ref.: https://bit.ly/2Pg5Uwu

24. Jani DB, 2019. Liquid desiccants application in cooling and dehumidification - An overview. Archives of Industrial Engineering. 2: 1-17.

25. Jain S, Dhar PL. 1995. Evaluation of solid-desiccant-based evaporative cooling cycles for typical hot and humid climates. Int J Ref. 18: 287-296. Ref.: https://bit.ly/2YoNi1P

26. Narayanan R. 2017. Investigation of geometry effects of channels of a silica-gel desiccant wheel. Energy Procedia. 110: 20-25. Ref.: https://bit.ly/2Pdnots

27. Joshi A, Jani DB. 2018. A review on desiccant based cooling and dehumidification systems. Int J Inn Knowledge Con. 6: 218-221.

28. Liu XH, Zhang T, Zheng TW, et al. 2016. Performance investigation and exergy analysis of two-stage desiccant wheel systems. Renewable Energy. 86: 877-888. Ref.: https://bit.ly/34L26dq

29. White SD, Kohlenbach P, Bongs C. 2009. Indoor temperature variations resulting from solar desiccant cooling in a building without thermal backup. Int J Refrig. 32: 695-704. Ref.: https://bit.ly/33L8wrx

30. Jani DB, Mishra M, Sahoo PK. 2018. Performance analysis of a solid desiccant assisted hybrid space cooling system using TRNSYS. Journal of Building Engineering. 19: 26-35. Ref.: https://bit.ly/2LkNbyC

31. Worek WM, Moon CJ. 1986. Simulation of an integrated hybrid desiccant vapor-compression cooling system. Energy. 11: 1005-1021. Ref.: https://bit.ly/2Royw9P

32. Jani DB, Lalkiya D, Patel S. 2018. A critical review on evaporative desiccant cooling. Int J Inno Emerg Res Eng. 5: 24-29.

33. Hwang WB, Choi S, Lee DY. 2017. In-depth analysis of the performance of hybrid desiccant cooling system incorporated with an electric heat pump. Energy. 118: 324-332. Ref.: https://bit.ly/2PbaD2B

34. Jani DB, Mishra M, Sahoo PK. 2017. Application of artificial neural network for predicting performance of solid desiccant cooling systems- A review. Renewable and Sustainable Energy Reviews. 80: 352-366. Ref.: https://bit.ly/2sE3pwo

35. Beccali M, Finocchiaro P, Nocke B. 2012. Energy performance evaluation of a demo solar desiccant cooling system with heat recovery for the regeneration of the adsorption material. Renew. Energy. 44: 40-52. Ref.: https://bit.ly/2r3A8em

36. Jani DB, Shah N, Panchal N. 2018. A review on application of desiccant dehumidification - vapor compression hybrid cooling system in hot-humid climates. Int J Inno Emerg Res Eng. 5: 1-5.

37. Merabti L, Merzouk M, Merzouk NK, et al. 2017. Performance study of solar driven solid desiccant cooling system under Algerian coastal climate. Int J Hydrogen Energy. 42: 28997-29005. Ref.: https://bit.ly/34Oggue

38. Jani DB, Bhabhor KK, Dadi M, et al. 2019. A review on use of TRNSYS as simulation tool in performance prediction of desiccant cooling cycle. Journal of Thermal Analysis and Calorimetry. Ref.: https://bit.ly/2qklRtl

39. Fong KF, Chow TT, Lee CK, et al. 2010. Advancement of solar desiccant cooling system for building use in subtropical Hong Kong. Energy Build. 42: 2386-2399. Ref.: https://bit.ly/360hqTt

40. Jani DB. 2019. An overview on recent development in desiccant materials. International Journal of Advanced Materials Research. 5: 31-37.

41. Patanwar P, Shukla SK, 2014. Mathematical modelling and experimental investigation of the hybrid desiccant cooling system. Int J Sustain Energy. 33: 103-111. Ref.: https://bit.ly/2YdhGMt

42. Jani DB, Mishra M, Sahoo PK. 2016. Exergy analysis of solid desiccant - vapor compression hybrid air conditioning system. International Journal of Exergy. 20: 517-535. Ref.: https://bit.ly/2Ligj9J

43. Narayanan R, Halawa E, Jain S. 2018. Performance characteristic of solid-desiccant evaporative cooling system. Energies. 11: 25-74. Ref.: https://bit.ly/2rfYYrp

44. Bhabhor KK, Jani DB. 2019. Progressive development in solid desiccant cooling: A review. International Journal of Ambient Energy. Ref.: https://bit.ly/2rbv6MN

45. Speerforck A, Ling J, Aute V, et al. 2017. Modeling and simulation of a desiccant assisted solar and geothermal air conditioning system. Energy. 141: 2321-2336. Ref.: https://bit.ly/38608Go

46. Jani DB, Mishra M, Sahoo PK. 2016. Performance prediction of solid desiccant - vapor compression hybrid air-conditioning system using artificial neural network. Energy. 103: 618-629. Ref.: https://bit.ly/2DIcXbZ

47. Comino F, de Adana MR, Peci F. 2018. Energy saving potential of a hybrid HVAC system with a desiccant wheel activated at low temperatures and an indirect evaporative cooler in handling air in buildings with high latent loads. Appl Therm Eng. 131: 412-427. Ref.: https://bit.ly/2YfyfqR

48. Jani DB, Mishra M, Sahoo PK. 2016. Performance analysis of hybrid solid desiccant - vapor compression air-conditioning system in hot and humid weather of India. Building Services Engineering Research and Technology. 37: 523-538. Ref.: https://bit.ly/38e4YBI

49. Tu R, Hwang Y. 2018. Efficient configurations for desiccant wheel cooling systems using different heat sources for regeneration. Int J Refrig. 86: 14-27. Ref.: https://bit.ly/384xUfi

50. Fong KF, Lee CK. 2018. New perspectives in solid desiccant cooling for hot and humid regions. Energy Build. 158: 1152-1160. Ref.: https://bit.ly/2DFNAI1

51. Jani DB, Mishra M, Sahoo PK. 2016. Performance prediction of rotary solid desiccant dehumidifier in hybrid air-conditioning system using artificial neural network. Applied Thermal Engineering. 98: 1091-1103. Ref.: https://bit.ly/2YfyBOd

52. Camargo JR, Ebinuma CD. 2005. An evaporative and desiccant cooling system for air conditioning in humid climates. J Braz Soc Mech Sci Eng. 27: 243-247. Ref.: https://bit.ly/2OLmLs0

53. Ma Y, Saha SC, Miller W, et al. 2017. Comparison of Different Solar-Assisted Air Conditioning Systems for Australian Office Building. Energies. 10: 1463-1473. Ref.: https://bit.ly/37YtDtT

54. Merabti L, Merzouk M, Merzouk NK, et al. 2017. Performance study of solar driven solid desiccant cooling system under Algerian coastal climate. Int J Hydrogen Energy. 42: 28997-29005. Ref.: https://bit.ly/3893uZx

55. Bareschino P, Pepe F, Roselli C, et al. 2019. Desiccant-Based Air Handling Unit Alternatively Equipped with Three Hygroscopic Materials and Driven by Solar Energy. Energy. 12: 1543-1557. Ref.: https://bit.ly/2r32kOv

56. Speerforck A, Ling J, Aute V, et al. 2017. Modeling and simulation of a desiccant assisted solar and geothermal air conditioning system. Energy. 141: 2321-2336. Ref.: https://bit.ly/2LhHguk

57. Pandelidis D, Pacak A, Cichon A, et al. 2018. Multi-stage desiccant cooling system for moderate climate. Energy Converse Manage. 177: 77-90. Ref.: https://bit.ly/2LmOQDU

58. Heidari A, Roshadel R, Vakiloroaya V. 2019. An innovative solar assisted desiccant based evaporative cooling system for co-production of water and cooling in hot and humid climates.

Energy Converse Manage. 396-409. Ref.: https://bit.ly/2Pesu8G

59. Shahzad MK, Qadar Chaudhary G, Ali M, et al. 2018. Experimental evaluation of a solid desiccant system integrated grated with cross flow Maisotsenko cycle evaporative cooler. Appl Therm Eng. 128: 1476-1487. Ref.: https://bit.ly/2RlGZKH

60. Chung HJ, Jeon Y, Kim D, et al. 2017. Performance characteristics of domestic hybrid dehumidifier combined with solid desiccant rotor and vapor compression system. Energy. 141: 66-75. Ref.: https://bit.ly/362u0BP

61. Comino F, Ruiz de Adana M, Peci F. 2018. Energy saving potential of a hybrid HVAC system with a desiccant wheel activated at low temperatures and an in-direct evaporative cooler in handling air in buildings with high latent loads. Appl Therm Eng. 131: 412-427. Ref.: https://bit.ly/384yHwM

62. Samuel de AB, Santos FJD, Pinheiro PR, et al. 2017. Dynamic evaluation of the energy efficiency of environments in Brazilian university classrooms using DEA. Sustainability. 9: 1-14. Ref.: https://bit.ly/2qjrpUV